- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

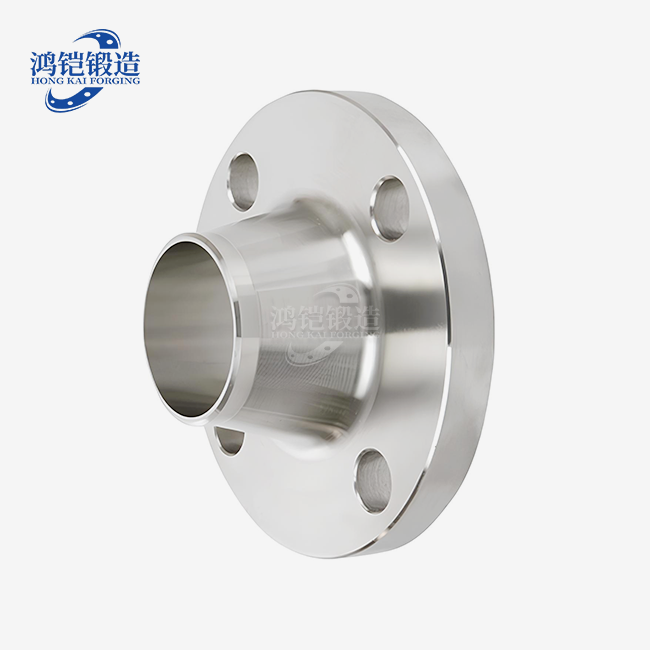

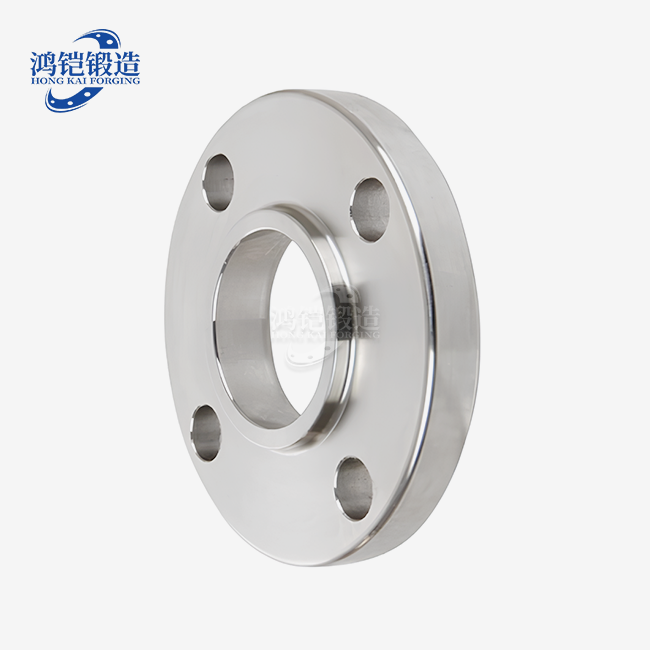

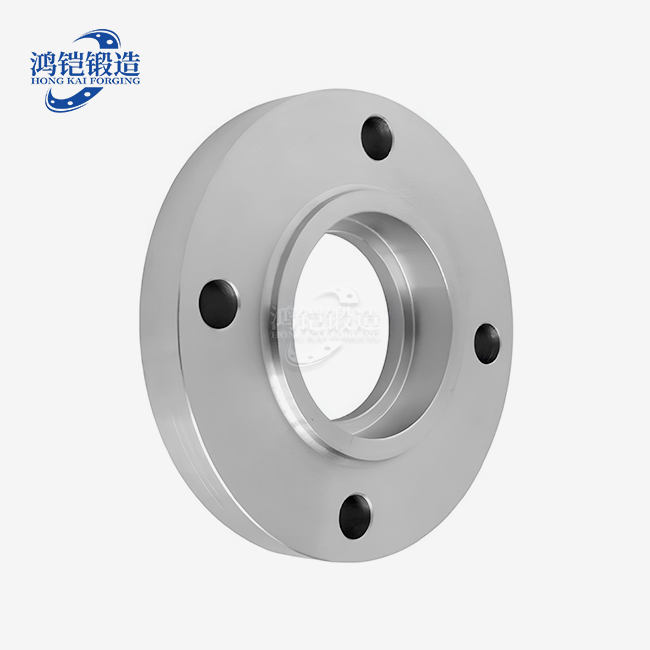

Blind Flange

It complies with standards like ANSI/ASME B16.5, DIN, EN 1092-1, and GOST , available in PN6-PN160 and DN15-DN5000, with materials including carbon steel, stainless steel, and alloy steel.

Applied in oil refineries, chemical plants, pipelines, and pressure vessels for end sealing.

Blind Flange - Professional Pipe Termination Solutions

Shanxi Hongkai Forging Co., Ltd. specializes in manufacturing premium Blind Flange arrangements that meet worldwide industry benchmarks. Our enterprise-grade pipe end items include vigorous fixing execution with details extending from DN15 to DN4000 and weight evaluations from PN6 to PN160. With coordinates generation capabilities traversing fashioning, warm treatment, machining, and comprehensive quality review, we convey solid product components that comply with ASME B16.5, EN1092-1, DIN, and GOST standards for critical industrial applications worldwide.

What is Blind Flange

this is a strong plate component planned to totally seal pipe closes and avoid liquid spillage in your channeling frameworks. Not at all like conventional flanges with center bores, this specialized component needs any opening, making it idealize for line end applications.

You'll discover these closure plates priceless when you require secure, leak-proof seals for high-pressure line endings. They bear most extreme bowing push at the center whereas keeping up considerable gasket seating constrain around the edge. This building plan guarantees solid execution beneath requesting mechanical conditions.

The detachable nature of these components gives you simple get to for support, assessment, and future framework extension. You won't require cutting or welding operations when adjustment gets to be essential. Essentially expel the spine to get to your pipe insides or expand your channeling framework as necessities change.

Specifications

| Standard | Size Range | Pressure Rating | Material Options | Face Types |

|---|---|---|---|---|

| ASME B16.5 | DN15-DN600 | Class 150-2500 | Carbon Steel, SS 304/316L | RF, FF, RTJ |

| ASME B16.47 | DN650-DN5000 | Class 150-900 | Alloy Steel, Duplex SS | RF, RTJ |

| EN 1092-1 | DN15-DN4000 | PN6-PN160 | Carbon Steel, Stainless Steel | Type A, B, C |

| JIS B2220 | 15A-1500A | 10K-40K | Carbon Steel, SS 304/316 | RF, FF |

| DIN Standards | DN15-DN2000 | PN6-PN100 | Various Alloys | RF, FF |

Advantages of Blind Flange

Superior Fixing Execution: You get total stream confinement with zero spillage potential. The strong circle plan dispenses with any plausibility of liquid entry, guaranteeing supreme framework security.

Easy Support Get to: These components give detachable get to focuses for your channeling frameworks. You can rapidly dismantle segments for assessment, cleaning, or alterations without lasting alterations.

Cost-Effective Arrangement: Compared to welded caps, you spare cash on future adjustments. The reusable nature kills cutting and rewelding costs when framework changes ended up necessary.

High-Pressure Capability: Our Blind Flange products withstand extraordinary weight conditions. The expanded thickness plan handles full inside weight acting against the level surface effectively.

Versatile Applications: You can adjust these components for instrumented needs. Center or off-center penetrating obliges weight gages, deplete valves, or temperature sensors as required.

Applications

Petrochemical Industry: You'll utilize these components for separating pipeline segments amid upkeep shutdowns. They handle high-pressure hydrogen and hydrocarbon streams with RTJ facings for extraordinary warm cycling conditions.

Water Treatment Frameworks: Metropolitan water offices depend on these flanges for transmission line end. The corrosion-resistant coatings handle crude water situations whereas encouraging future extension projects.

Marine Applications: Shipbuilding businesses utilize these components for assessment ports on tanks and vessels. Copper-nickel or duplex stainless steel materials stand up to chloride push erosion in saltwater environments.

Power Era: Warm and atomic control plants depend on these spines for steam line confinement. High-temperature amalgam materials keep up judgment beneath extraordinary working conditions.

Chemical Handling: Fabricating offices utilize these components for reactor vessel segregation and prepare line end. Different fabric grades oblige diverse chemical compatibility requirements.

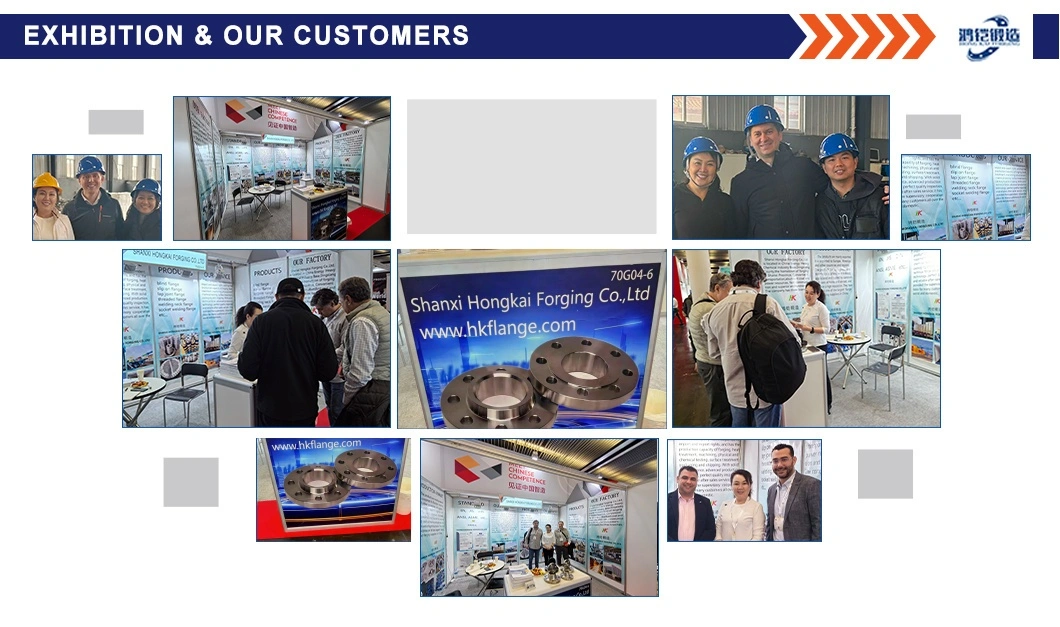

Why Choose Us

Global Standards Compliance: We manufacture products meeting ASME, EN, DIN, JIS, and GOST specifications. Your projects receive components that satisfy international quality requirements across different markets.

Comprehensive Generation Capabilities: Our coordinates offices handle each fabricating organize from producing to last bundling. You get items with reliable quality control all through the whole generation process.

Extensive Estimate Extend: We offer determinations from DN15 to DN5000 with weight evaluations up to PN160. Your assorted venture necessities get fitting arrangements notwithstanding of application scale.

Quality Assurance: Our physical and chemical testing capabilities ensure product reliability. Each Blind Flange experiences intensive assessment some time recently conveyance to ensure execution standards.

International Involvement: With trade operations to Europe and Americas, we get it worldwide advertise prerequisites. Your ventures advantage from our encounter serving universal mechanical standards.

FAQ

Q: Why are these flanges thicker than slip-on flanges of the same rating?

A: The solid disc must withstand full internal pressure acting against its flat surface. ASME B16.5 requires greater thickness to prevent deformation compared to bored flanges.

Q: Can you drill and tap flanges for instrumentation?

A: Yes, we can create NPT threaded holes for pressure gauges or drain valves. This modification follows engineering specifications to maintain pressure ratings.

Q: When should I specify RTJ facings?

A: RTJ facings work best for high-pressure applications (Class 600+) and high temperatures. The metal-to-metal seal provides superior leak protection in severe conditions.

Q: What's the difference between these and spectacle blinds?

A: Standard versions terminate lines permanently or semi-permanently. Spectacle blinds rotate between open and closed positions for temporary isolation during maintenance.

Q: Do high-pressure versions include hubs?

A: Class 900 and above products may feature back-side hubs for increased rigidity. This design reduces material requirements while meeting strength standards.

Contact Us

Ready to discuss your Blind Flange requirements? Contact our technical team at kevin.zhao@hkflange.com for expert guidance and competitive quotations.

Clear Communication, and Reliable Technical Support