- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

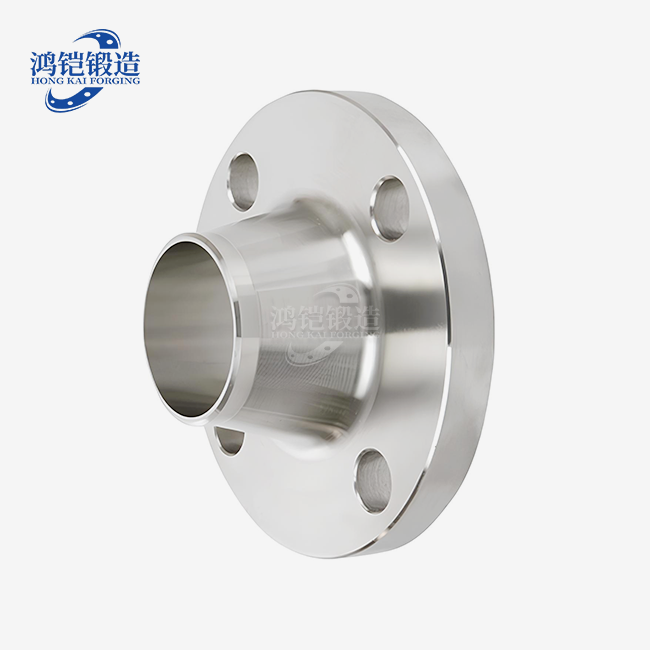

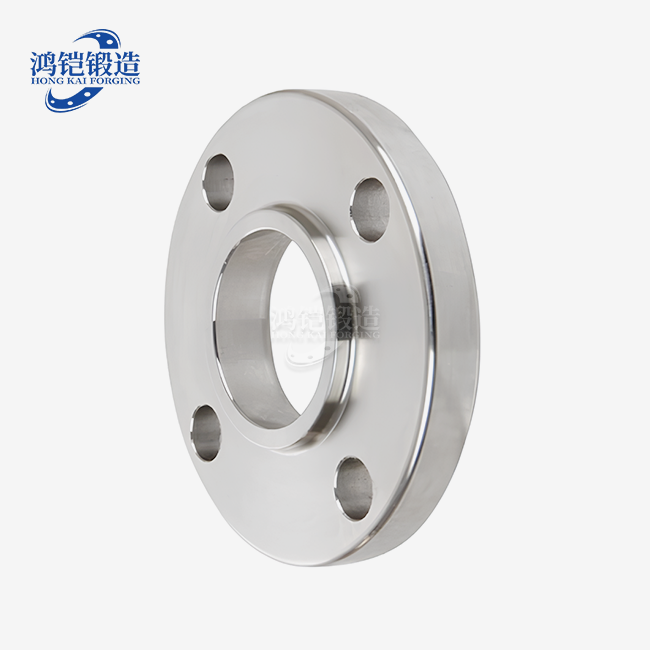

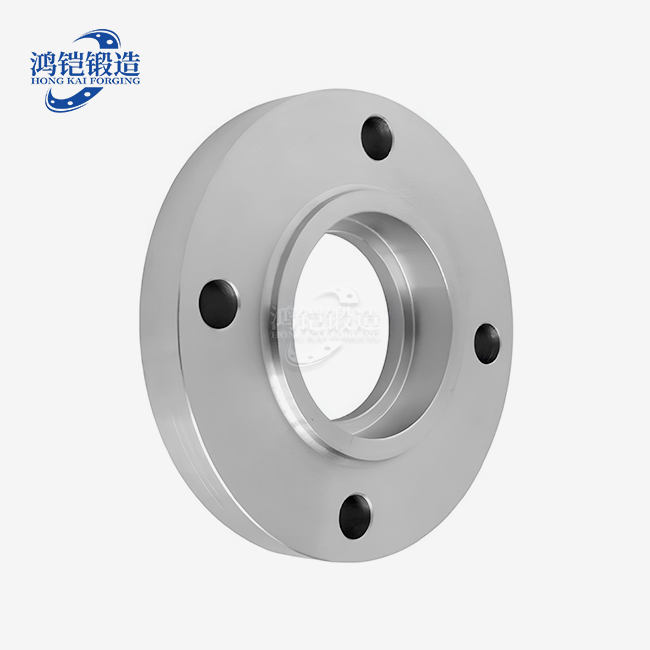

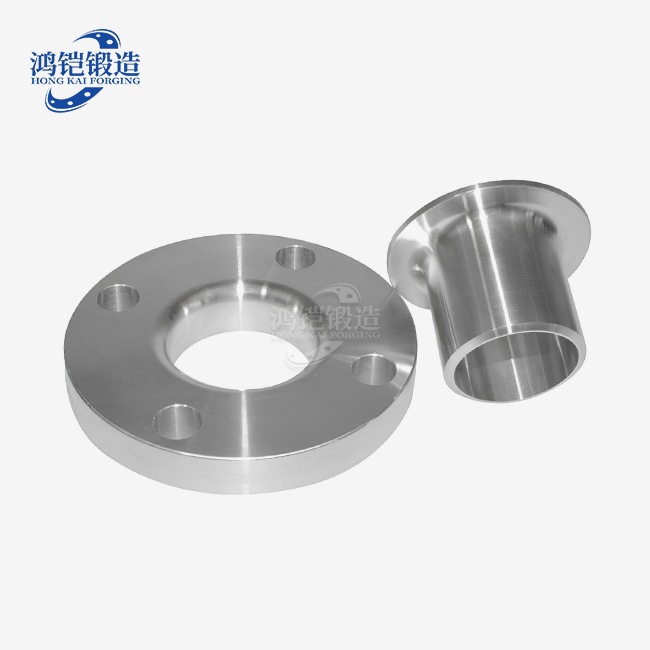

Threaded Flange

It complies with standards like ANSI/ASME B16.5, DIN, EN 1092-1, and GOST , available in PN6-PN160 and DN15-DN5000, with materials including carbon steel, stainless steel, and alloy steel.

Applied in water treatment, plumbing, low-pressure gas systems, and light industrial pipelines.

Threaded Flange - Professional Industrial Piping Solutions

Shanxi Hongkai Forging Co., Ltd specializes in manufacturing precision Threaded Flange products that meet the most requesting mechanical prerequisites. Our screwed spines include decreased inner strings acclimating to ASME B1.20.1 guidelines, giving dependable mechanical associations without welding. With weight evaluations from Class 150 to Class 2500 and sizes ranging DN15-DN4000, we convey enterprise-grade arrangements that dispense with hot-work licenses in perilous situations. Our items accomplish 40-60% speedier establishment times compared to welded options, making them perfect for unstable environments and galvanized channeling frameworks where keeping up defensive coatings is critical.

What is Threaded Flange

This is a specialized channeling component highlighting inside decreased strings that mechanically interface to pipe outside strings. Not at all like welded flanges, this plan makes secure associations through string impedances or maybe than combination welding.

The decreased string profile takes after a 60° point with smoothed crests and valleys. As you fix the association, the strings compress together, shaping a metal-to-metal seal. This mechanical joining strategy dispenses with heat-affected zones that can compromise pipe integrity.

These flanges unravel basic industry challenges. They're fundamental when welding makes security dangers in dangerous situations. You can introduce them in chemical plants, refineries, and grain offices without hot-work licenses. They too protect defensive coatings on galvanized channels that welding would destroy.

Specifications

| Parameter | Details |

|---|---|

| Standards | ASME B16.5, EN 1092-1, DIN, JIS B2220, GOST |

| Pressure Ratings | PN6-PN160, Class 150-Class 2500 |

| Size Range | DN15-DN5000 (NPS ½"-24") |

| Thread Type | NPT per ASME B1.20.1 |

| Materials | Carbon Steel (ASTM A105), Stainless Steel (ASTM A182 F304/F316), Alloy Steel |

| Temperature Range | -29°C to 538°C depending on material |

| Face Types | Raised Face (RF), Flat Face (FF) |

| Testing | Hydrostatic pressure testing per applicable standards |

Advantages of Threaded Flange

Installation Efficiency

You'll decrease establishment time by 40-60% compared to welded spines. No welding implies no X-ray assessments or cooling time. Your teams can total associations speedier with straightforward threading tools.

Safety in Hazardous Environments

These spines dispose of start dangers amid establishment. You can securely interface channeling in hazardous airs without complex hot-work grants. This makes them idealize for dynamic refineries and chemical plants.

Coating Preservation

Threading jam galvanized and other defensive coatings. Welding annihilates these obstructions, but our product connections keep up erosion assurance keenness all through the framework lifecycle.

Maintenance Flexibility

You can dismantle associations without cutting or pounding. This non-destructive expulsion underpins hardware support and framework adjustments. It's perfect for transitory establishments and pilot plants.

Applications

Oil and Gas Industry

Refineries utilize items for instrument discuss lines and assistant channeling in unstable zones. You'll discover them on small-bore hydrocarbon lines where welding grants are troublesome to obtain.

Water Treatment Systems

Municipal offices depend on these flanges for galvanized water dissemination systems. They interface valves and hardware whereas protecting pipe coatings that avoid corrosion.

Fire Protection Systems

Commercial buildings use threaded flange connections in sprinkler systems. The preserved galvanization ensures long-term system reliability without welding damage.

Hydraulic Power Units

High-pressure hydraulic systems utilize these flanges for vibration-resistant connections. They provide leak-resistant seals in dynamic applications where welded joints might fail.

Chemical Processing

Plants handling corrosive materials benefit from stainless steel products. You avoid heat-affected zones that could create corrosion initiation points.

Why Choose Us

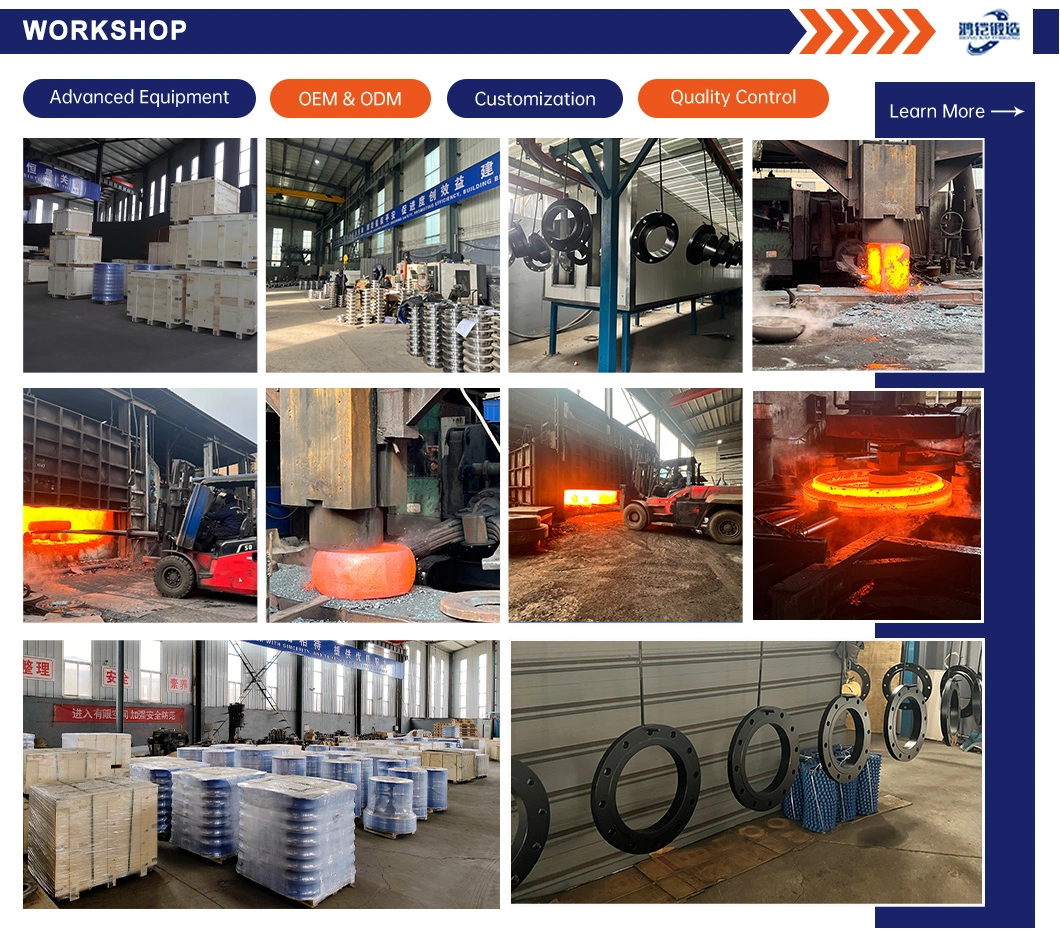

Manufacturing Excellence

Shanxi Hongkai Forging brings decades of skill in mechanical spine generation. We work coordinates offices with fashioning, warm treatment, machining, and testing capabilities beneath one roof.

Global Standards Compliance

Our products meet international standards including ASME, EN, DIN, and JIS specifications. You receive consistent quality regardless of your project location or requirements.

Comprehensive Size Range

We make spines from DN15 to DN4000, covering essentially any application. Our generation capacity handles both standard and custom details efficientl

Quality Assurance

Every item experiences thorough testing counting dimensional confirmation and weight testing. Our quality frameworks guarantee solid execution in requesting applications.

Technical Support

Our designing group gives application direction and specialized interview. We offer assistance you select ideal spine determinations for your particular working conditions.

FAQ

Q: What's the maximum recommended size for threaded flanges?

A: We recommend sizes up to NPS 4 for optimal seal integrity. Larger sizes may experience leakage risks under thermal cycling.

Q: Can threaded flanges handle high temperatures?

A: Yes, with proper material selection. Alloy steel grades handle temperatures up to 538°C, though thermal expansion considerations apply.

Q: Do you provide custom threading specifications?

A: We primarily manufacture NPT threads per ASME B1.20.1. Contact us for special threading requirements and feasibility assessment.

Q: What sealants work best with your flanges?

A: PTFE tape or approved pipe dope compounds provide excellent sealing. Avoid over-tightening which can damage threads.

Q: How do delivery times compare to welded flanges?

A: Our products typically ship faster since they require less post-machining processing than weld-neck alternatives.

Contact Us

Ready to discuss your threaded flange requirements? Contact kevin.zhao@hkflange.com for technical consultation and competitive pricing on your next project.

Clear Communication, and Reliable Technical Support