- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

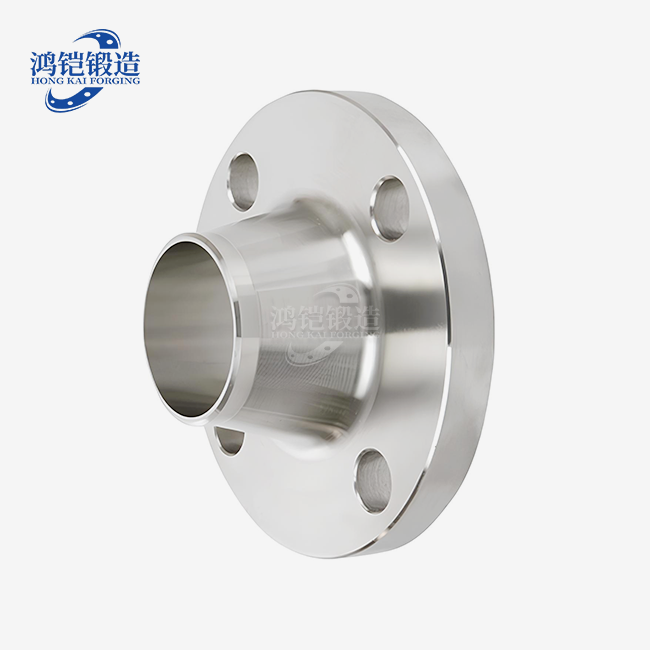

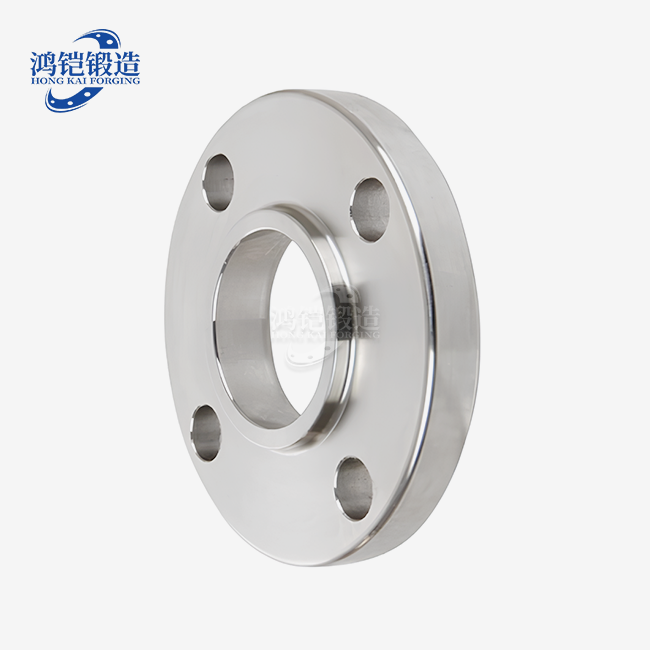

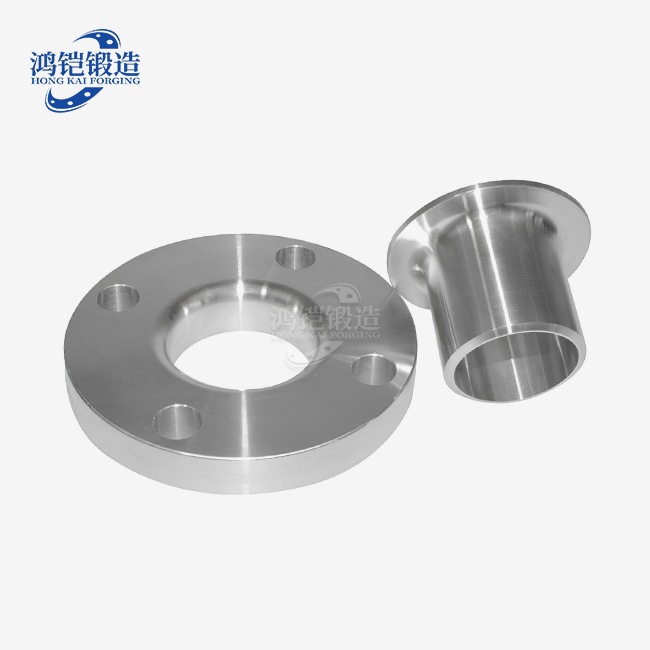

Socket Weld Flange

It complies with standards like ANSI/ASME B16.5, DIN, EN 1092-1, and GOST , available in PN6-PN160 and DN15-DN5000, with materials including carbon steel, stainless steel, and alloy steel.

Ideal for instrumentation, hydraulic systems, nuclear power, and small-bore process pipelines.

Socket Weld Flange - High-Performance Piping Solutions by Shanxi Hongkai Forging

When it comes to reliable small-bore piping connections, our Socket Weld Flange stands as the industry standard for high-pressure applications. At Shanxi Hongkai Forging Co., Ltd.,we fabricate premium items that provide extraordinary auxiliary judgment with 50% higher weakness quality than ordinary slip-on plans. Our socket flanges highlight precision-machined counterbores that dispense with arrangement issues whereas giving airtight fixing for harmful and combustible media. With determinations extending from DN15 to DN4000 and pressure ratings up to Class 2500, our products meet stringent ASME B16.5, EN1092-1, and DIN standards for critical industrial applications.

What is Socket Weld Flange

This is a specialized channeling component outlined with a recessed counterbore that gets the pipe conclusion, making a vigorous association through outside filet welding. This plan anticipates inner weld bulge, making it perfect for applications where stream defilement must be avoided.

The socket plan acts as a normal arrangement direct, disposing of the require for tack welding amid establishment. This highlight demonstrates priceless in kept spaces where exact situating is challenging. Not at all like strung associations, socket weld flanges provide permanent, leak-proof joints suitable for hazardous media transportation.

The fabricating handle includes accuracy manufacturing taken after by cautious machining to guarantee correct dimensional resistances. Each flange experiences thorough quality testing to meet worldwide guidelines and convey steady execution in requesting environments.

Specification

Our socket weld flanges are manufactured to meet multiple international standards:

| Standard | Size Range | Pressure Rating | Material Options |

|---|---|---|---|

| ASME B16.5 | NPS 1/8" - 4" | Class 150-2500 | ASTM A105, A182 F304/316L |

| EN 1092-1 | DN6 - 100 | PN16 - PN400 | Carbon Steel, Stainless Steel |

| JIS B2220 | DN6 - 100 | 10K - 40K | Alloy Steel grades available |

| DIN Standard | DN15 - DN100 | PN6 - PN160 | Custom materials on request |

Key Technical Features:

- Expansion gap: 1/16 inch (1.6mm) standard

- Face finish: 125-250 RMS per ASME B16.5

- Hardness: HB ≤ 200 for carbon steel grades

- Temperature range: -29°C to +400°C depending on material

Advantages of Socket Weld Flange

Superior Structural Performance

Our socket weld flanges offer uncommon weariness resistance, making them culminate for high-vibration situations. The single outside filet weld plan gives quality whereas permitting simple visual inspection.

Leak-Proof Design

The socket arrangement makes a positive seal that avoids criminal emanations. This highlight is vital for harmful or costly media where zero spillage is mandatory.

Installation Efficiency

The built-in arrangement highlight diminishes establishment time and dispenses with welding mistakes. Specialists can accomplish legitimate fit-up rapidly, indeed in challenging field conditions.

Cost-Effective Solution

While giving execution comparative to butt weld flanges, socket welds require less accuracy cutting and planning, lessening by and large extend costs.

Quality Assurance

Every spine experiences comprehensive testing counting dimensional confirmation, fabric certification, and weight testing to guarantee dependable long-term performance.

Applications

High-Pressure Hydraulic Systems

Socket weld flanges excel in pressure driven activation frameworks where ceaseless vibration and weight surges would compromise strung associations. Control era and overwhelming apparatus applications depend on these spines for basic pressure driven control systems.

Petrochemical Processing

Refineries utilize these flanges in harmful refining lines where control astuteness is vital. The outside weld plan permits for simple review whereas avoiding inner defilement of catalysts and handle media.

Steam Generation Systems

Power plants depend on socket weld spines for superheated steam inspecting lines and instrumented associations. The plan withstands warm cycling way better than strung options, decreasing support requirements.

Instrumentation and Control

Process businesses utilize these flanges for instrument associations, analyzer test lines, and small-bore prepare channeling where unwavering quality cannot be compromised.

Why Choose Us

Manufacturing Excellence

Shanxi Hongkai Forging operates three advanced production facilities with integrated capabilities including forging, heat treatment, machining, and comprehensive testing. Our strategic location in Shanxi Province provides access to abundant raw materials and energy resources.

Global Standards Compliance

We maintain certifications for ASME, EN, DIN, JIS, GOST, and Chinese national benchmarks, guaranteeing your ventures meet nearby and universal necessities notwithstanding of location.

Quality Control System

Our comprehensive quality management includes material traceability, dimensional inspection, non-destructive testing, and pressure testing. Each Socket Weld Flange comes with complete documentation and certificates.

Competitive Advantages

- Superior quality with competitive pricing

- Fast conveyance with dependable packaging

- Technical bolster all through extend lifecycle

- Extensive stock for quick shipment

International Reach

With built up send out connections over Europe and the Americas, we get it worldwide showcase necessities and give localized bolster for universal projects.

FAQ

Q: What is the expansion gap requirement for socket weld installation?

A: Industry standards require approximately 1/16 inch (1.6mm) gap between pipe end and socket bottom. This prevents weld cracking during thermal expansion.

Q: Can socket weld flanges handle corrosive environments?

A: Yes, when manufactured from appropriate materials like 316L stainless steel. However, the internal crevice requires monitoring in highly corrosive stagnant fluids.

Q: What NDT methods are used for inspection?

A: Socket welds are inspected using Magnetic Particle Testing (MT) or Liquid Penetrant Testing (PT) for surface defect detection, as radiographic testing isn't applicable to fillet welds.

Q: Why is size typically limited to NPS 4?

A: Larger sizes experience welding heat distortion issues and become less cost-effective compared to butt weld alternatives.

Q: What materials are available for high-temperature service?

A: We offer ASTM A182 F11 and F22 alloy steel grades for elevated temperature applications up to 650°C, along with standard carbon and stainless steel options.

Contact Us

Quality Socket Weld Flange solutions ensure your piping systems operate safely and efficiently for years to come.

Ready to discuss your product requirements? Contact our technical team at kevin.zhao@hkflange.com for expert guidance and competitive pricing.

Clear Communication, and Reliable Technical Support