- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

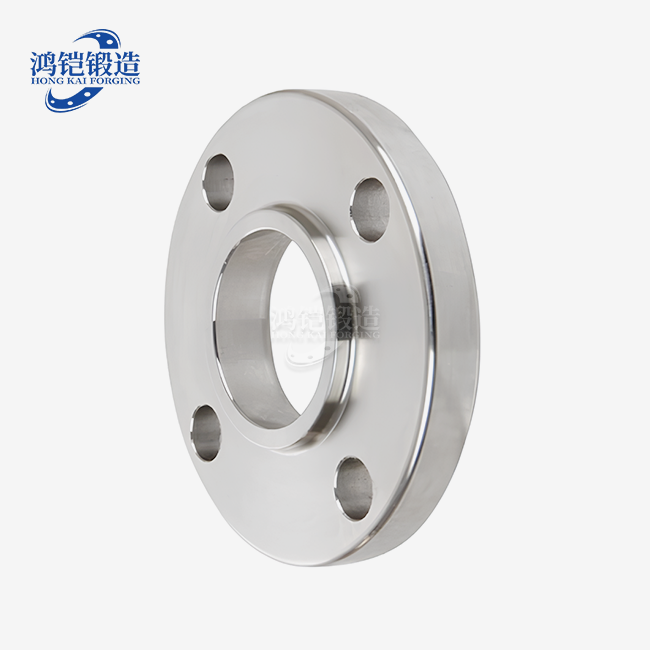

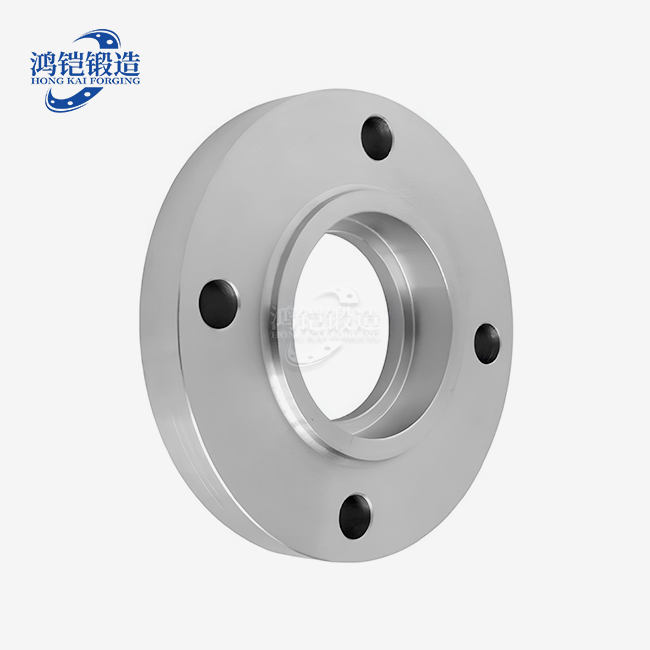

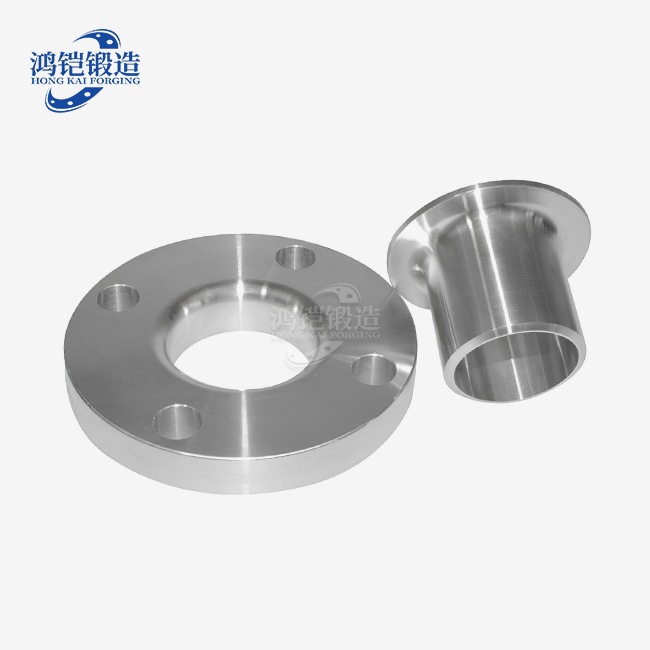

Weld Neck Flange

It complies with standards like ANSI/ASME B16.5, DIN, EN 1092-1, and GOST , available in PN6-PN160 and DN15-DN5000, with materials including carbon steel, stainless steel, and alloy steel.

Widely used in oil and gas, petrochemical, power generation, and chemical processing industries.

Weld Neck Flange - High-Performance Industrial Connection Solution

Shanxi Hongkai Forging Co., Ltd. specializes in manufacturing premium Weld Neck Flange products with integrated production capabilities spanning forging, heat treatment, machining, and comprehensive quality testing. Our enterprise-level solutions feature specifications ranging from DN15 to DN4000, pressure ratings up to Class 2500, and compliance with multiple international standards including ASME B16.5, EN1092-1, and DIN. With three department workplaces and free import-export rights, we provide prevalent channeling association arrangements for requesting mechanical applications worldwide.

What is Weld Neck Flange

This is a high-integrity channeling component planned for butt-welding specifically to channels. This specialized flange highlights a particular long, decreased center that makes a progressive move from the flange confront to the pipe wall.

The decreased plan gives extraordinary push dispersion, moving concentration absent from the flange base to the pipe itself. This designing approach essentially progresses weakness quality beneath overwhelming twisting minutes and cyclic stacking conditions.

The bore of the spine is absolutely machined to coordinate the internal distance across of the interfacing pipe. This makes a consistent stream way that disposes of turbulence and diminishes erosion-corrosion in your channeling systems.

Specification

| Standard | Size Range | Pressure Rating | Material Options |

|---|---|---|---|

| ASME B16.5 | NPS ½" ~ 24" | Class 150 ~ 2500 | Carbon Steel, Stainless Steel, Alloy Steel |

| ASME B16.47 | NPS 26" ~ 60" | Class 150 ~ 900 | A105, A182 F304/316L, A182 F11/F22 |

| EN 1092-1 | DN10 ~ 2000 | PN6 ~ PN400 | P250GH, 1.4301/1.4404, 13CrMo4-5 |

| JIS B2220 | DN10 ~ 1000 | 10K ~ 40K | SS400, SUS304/316L, SCPH2 |

| API 605 | Custom Sizes | Various Classes | API Specified Materials |

Additional Specifications:

- Face Types: Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ)

- Hub Length: Standard and Long Weld Neck variations

- Surface Finish: 125-250 µin Ra for sealing surfaces

- Dimensional Tolerance: ±1mm for standard sizes

Advantages of Weld Neck Flange

Superior Auxiliary Judgment: The butt-weld association gives the most noteworthy quality joint in flange innovation. You get greatest weight control and resistance to outside forces.

Excellent Weariness Resistance: The decreased center plan conveys stretch equitably, avoiding split start beneath cyclic stacking. Your frameworks encounter amplified benefit life in requesting applications.

Seamless Stream Characteristics: The coordinated bore disposes of stream limitations and turbulence. This decreases weight drop and minimizes erosion-corrosion in your channeling systems.

100% Review Capability: The butt-weld geometry permits total radiographic testing. You can confirm weld quality all through the whole joint for basic applications.

Thermal Extension Settlement: The progressive thickness move handles warm stresses successfully. Your associations stay leak-tight through temperature cycling.

Reduced Upkeep Necessities: The strong plan minimizes joint corruption over time. You advantage from lower lifecycle costs and diminished downtime.

Applications

Oil and Gas Industry: These flanges excel in high-pressure transmission pipelines and offshore platforms. The Weld Neck Flange withstands inside weights surpassing 5,000 PSI whereas standing up to weakness from wave stacking and outside mechanical stresses.

Power Era: Steam lines in warm control plants depend on these flanges for temperatures over 500°C. The decreased center obliges warm development without compromising seal judgment amid extraordinary warm cycling.

Chemical Preparing: Refineries utilize these flanges for unstable and unsafe liquid transport. The consistent stream way minimizes erosion-corrosion whereas the butt-welded association decreases criminal emanation risks.

Petrochemical Plants: Complex handling frameworks advantage from the prevalent joint judgment. You get solid execution in applications including destructive media and shifting weight conditions.

Subsea Operations: Deep-water establishments depend on these flanges where support get to is constrained. The weakness resistance and NDT capability guarantee long-term unwavering quality in destructive saltwater environments.

Why Choose Us

Comprehensive Fabricating Capabilities: We coordinated manufacturing, warm treatment, machining, testing, and bundling beneath one roof. You get steady quality control all through the whole generation process.

International Standards Compliance: Our products meet ASME, EN, DIN, JIS, and GOST standards. You can specify the exact requirements for your regional applications with confidence.

Extensive Estimate Run: From DN15 to DN4000, we cover essentially all mechanical necessities. Your ventures advantage from single-source obtainment convenience.

Quality Affirmation: Progressed testing offices guarantee each product meets details. You get certified items with total traceability documentation.

Global Trade Involvement: Our items serve markets over Europe and the Americas. You work with demonstrated providers who get it worldwide quality expectations.

Competitive Preferences: Prevalent quality, competitive estimating, secure bundling, and quick conveyance combine to back your extend timelines and budgets.

FAQ

Q: Why must the bore schedule be specified when ordering?

A: The flange bore must match your pipe wall thickness exactly to prevent flow disruption and ensure proper weld radiography.

Q: How does this differ from Slip-On Flanges in performance?

A: Butt welding provides higher fatigue strength and pressure integrity compared to fillet-welded slip-on alternatives.

Q: Can these flanges use Ring Type Joint facings?

A: Yes, RTJ facings are standard for Class 600 and above applications requiring metal-to-metal sealing.

Q: What is a Long Weld Neck flange?

A: LWN flanges feature extended hubs that act as self-reinforcing nozzles for pressure vessel connections.

Q: What inspection methods are required?

A: Radiographic or ultrasonic testing is typically mandatory for volumetric weld inspection in critical piping applications.

Contact Us

Ready to enhance your piping systems with premium Weld Neck Flange solutions? Contact kevin.zhao@hkflange.com for technical specifications and competitive quotations today.

Clear Communication, and Reliable Technical Support