- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

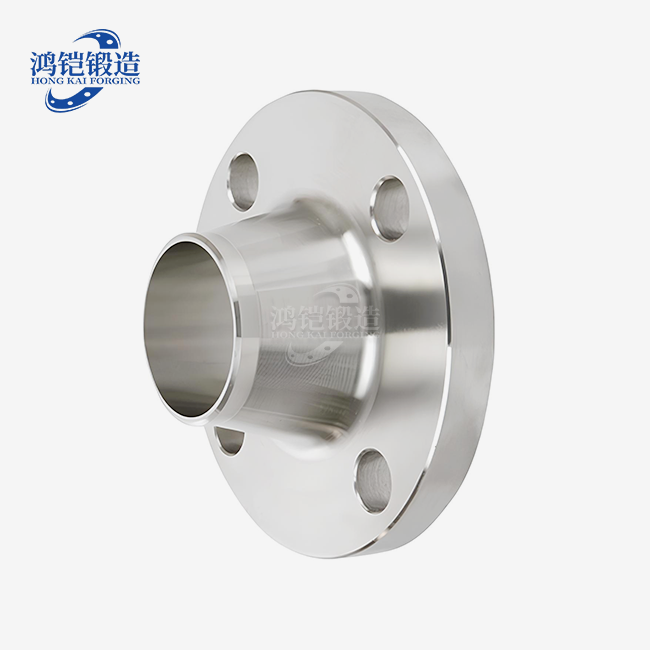

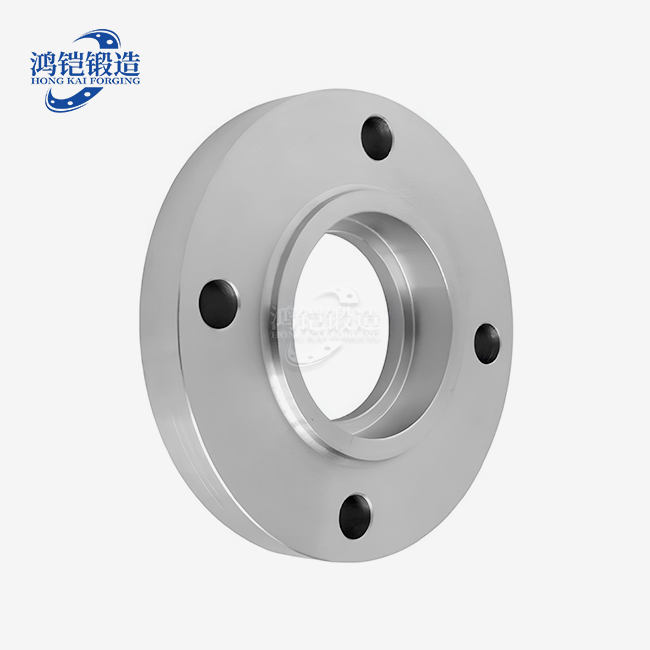

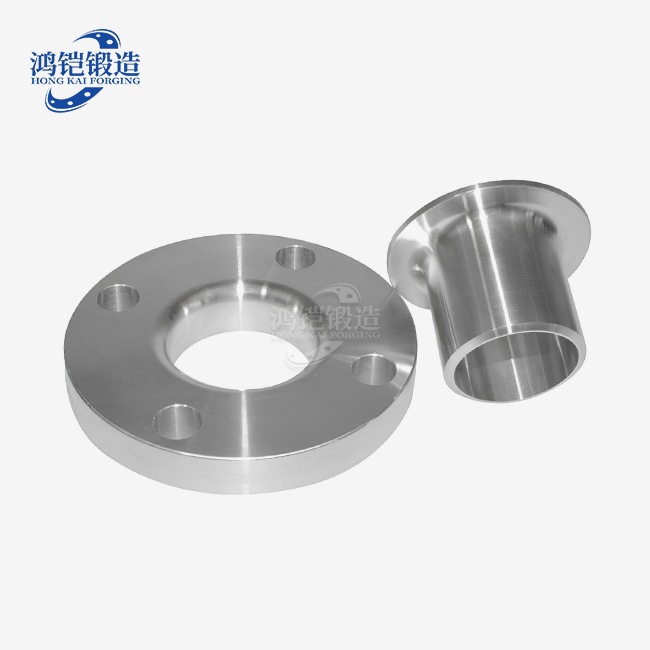

Slip On Flange

It complies with standards like ANSI/ASME B16.5, DIN, EN 1092-1, and GOST , available in PN6-PN160 and DN15-DN5000, with materials including carbon steel, stainless steel, and alloy steel.

Used in general manufacturing, water supply, heating, and low-pressure chemical pipelines.

Slip On Flange - Premium Quality Piping Solutions

Shanxi Hongkai Forging Co., Ltd delivers enterprise-grade Slip On Flange arrangements with determinations extending from DN15 to DN4000 and weight evaluations from PN6 to PN160. Our slip-on flanges highlight coordinates generation capabilities counting producing, warm treatment, machining, and comprehensive quality testing. These flanges slide over pipe closes and give cost-effective welding arrangements for medium-low weight applications. With conformance to ASME B16.5, EN1092-1, Commotion, and numerous universal guidelines, our items serve clients over Europe and the Americas with solid execution and competitive pricing.

What is Slip On Flange

This is a sort of pipe spine that slides over the conclusion of a pipe some time recently being filet welded in put. Not at all like weld neck spines, it doesn't require beveled pipe closes, making arrangement much simpler amid installation.

This flange sort is welded both interior and exterior to guarantee auxiliary judgment. The plan permits for slight alterations in pipe length amid manufacture, understanding common arrangement challenges in complex channeling systems.

The direct quality characteristics make it idealize for applications where tall weakness resistance isn't basic. You'll discover these spines offer fabulous esteem when cost-efficiency things most.

Specification

| Parameter | Range | Standards |

|---|---|---|

| Size Range | DN15 - DN4000 (NPS ½" - 24") | Multiple International Standards |

| Pressure Rating | PN6 - PN160 (Class 150 - 600) | ASME B16.5, EN 1092-1 |

| Material | Carbon Steel, Stainless Steel, Alloy Steel | ASTM A105, A182 F304/316 |

| Standards | ASME B16.5, EN 1092-1, DIN, JIS B2220 | 10K - 40K |

| Bore Diameter | Precision machined to pipe specifications | ±0.1mm tolerance |

| Hub Profile | Lower profile design | Weight optimized |

Advantages of Slip On Flange

Cost-Effective Arrangement: Our slip-on spines offer critical investment funds compared to weld neck choices. You get dependable execution at a division of the cost.

Easy Establishment: The slip-over plan streamlines arrangement amid creation. Your establishment group will appreciate the decreased complexity and speedier get together times.

Flexible Pipe Alteration: You can fine-tune pipe lengths after situating, disposing of exorbitant revamp. This adaptability demonstrates important in tight spaces or complex steering situations.

Lightweight Plan: The lower center profile decreases fabric weight whereas keeping up auxiliary judgment. This deciphers to less demanding taking care of and lower shipping costs.

Versatile Fabric Choices: Select from carbon steel for high-temperature benefit or stainless steel for erosion resistance. We coordinate materials to your particular application needs.

Quality Fabricating: Our coordinates generation handle guarantees steady quality from producing through last review. Each flange meets strict dimensional and fabric standards.

Applications

Industrial Utility Systems: Perfect for cooling water lines, compressed air systems, and low-pressure steam applications. The Slip On Flange excels in Class 150-300 utility networks where turbulence isn't a concern.

Fire Assurance Frameworks: Perfect for fire concealment plumbing and water dispersion systems. The simple arrangement highlight speeds establishment in kept mechanical rooms and building risers.

Petrochemical Operations: Appropriate for non-critical assistant lines in refineries and chemical plants. You'll discover them especially valuable for retrofitting existing frameworks in tight spaces.

Marine Building: Broadly utilized in shipbuilding for balance frameworks, tank venting, and bilge applications. The compact plan maximizes space effectiveness in vessel hulls.

HVAC Applications: Common in warming, ventilation, and discuss conditioning frameworks where direct weights and simple upkeep get to are priorities.

General Fabricating: Utilized all through fabricating offices for prepare water, plant discuss, and common utility associations. The cost-effectiveness makes them perfect for large-scale installations.

Why Choose Us

Three Decades of Expertise: Shanxi Hongkai Forging has built a notoriety as one of China's biggest flange providers. Our involvement interprets straightforwardly into item unwavering quality you can trust.

Comprehensive Fabricating: We control each step from crude materials through last shipping. This integration guarantees steady quality and competitive estimating for your projects.

Global Standards Compliance: Our products meet ASME, EN, DIN, JIS, and GOST standards. You receive flanges that integrate seamlessly with international piping systems.

Advanced Testing Capabilities: Every Slip On Flange undergoes rigorous physical and chemical testing. Our quality control process eliminates field failures and project delays.

Flexible Generation Capacity: From DN15 to DN4000, we make the total estimate run. Huge or little orders get the same consideration to detail and quality standards.

International Benefit Arrange: With three department workplaces and set up trade connections, we give dependable conveyance to Europe and the Americas.

Technical Bolster: Our designing group helps with fabric determination, determination compliance, and application direction. You get master bolster all through your venture lifecycle.

FAQ

Q: What pressure ratings are available for slip-on flanges?

A: We manufacture flanges from PN6 to PN160 (Class 150 to 600) depending on size and material specifications.

Q: How do slip-on flanges compare to weld neck flanges in terms of strength?

A: Slip-on flanges have approximately one-third the fatigue strength of weld neck flanges due to fillet weld stress concentration, making them ideal for static load applications.

Q: What materials do you offer for slip-on flanges?

A: We provide carbon steel (ASTM A105), stainless steel (ASTM A182 F304/316), and various alloy steels to match your application requirements.

Q: Can slip-on flanges be used in high-temperature applications?

A: Yes, with proper material selection. Carbon steel versions handle high temperatures, while stainless steel options provide excellent temperature and corrosion resistance.

Q: What's the typical delivery time for custom specifications?

A: Standard sizes ship within 2-3 weeks. Custom specifications typically require 4-6 weeks depending on complexity and quantity.

Q: Do you provide material test certificates?

A: Yes, every order includes complete material test certificates and dimensional inspection reports per your specification requirements.

Contact Us

Ready to discuss your Slip On Flange requirements? Contact our technical team at kevin.zhao@hkflange.com for expert guidance and competitive pricing.

Clear Communication, and Reliable Technical Support