- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Lap Joint Flange

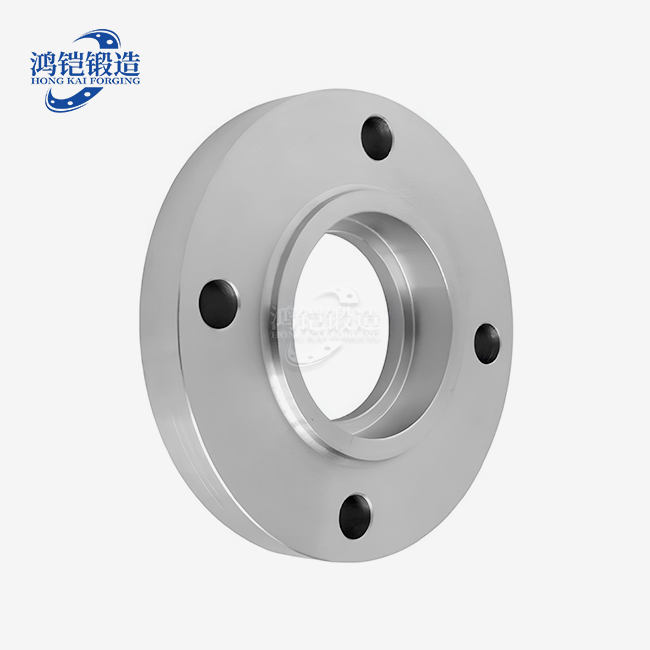

It complies with standards like ANSI/ASME B16.5, DIN, EN 1092-1, and GOST , available in PN6-PN160 and DN15-DN5000, with materials including carbon steel, stainless steel, and alloy steel.

Widely used in corrosive environments like marine, chemical, and food processing industries.

Lap Joint Flange - Professional Piping Solutions by Shanxi Hongkai Forging

Shanxi Hongkai Forging Co., Ltd specializes in manufacturing premium Lap Joint Flange assemblies that convey remarkable execution in requesting mechanical applications. Our two-component plan highlights a metallic backing ring and isolated stub conclusion, empowering 360° revolution for idealize arrangement whereas keeping up cost-effective arrangements for destructive situations. With details extending from DN15 to DN4000 and weight evaluations from PN6-PN160, our item frameworks comply with different worldwide measures counting ASME B16.5, EN1092-1, and DIN specifications, ensuring reliable performance across diverse piping networks worldwide.

What is Lap Joint Flange

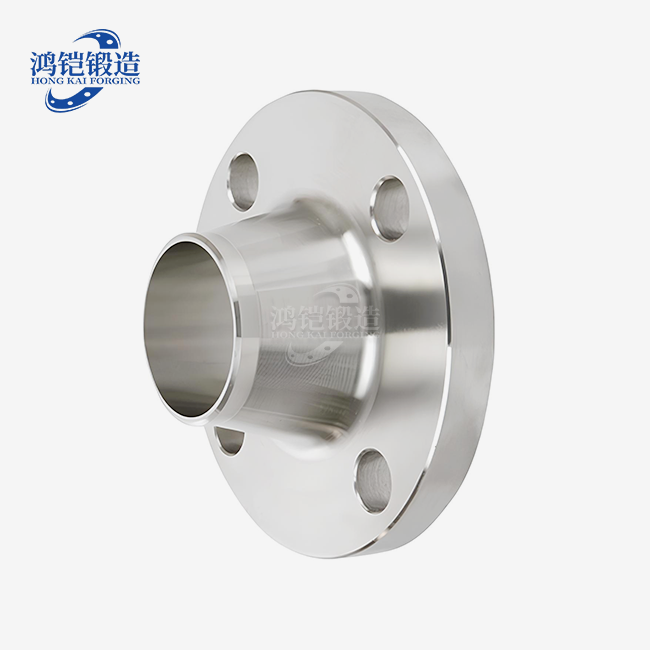

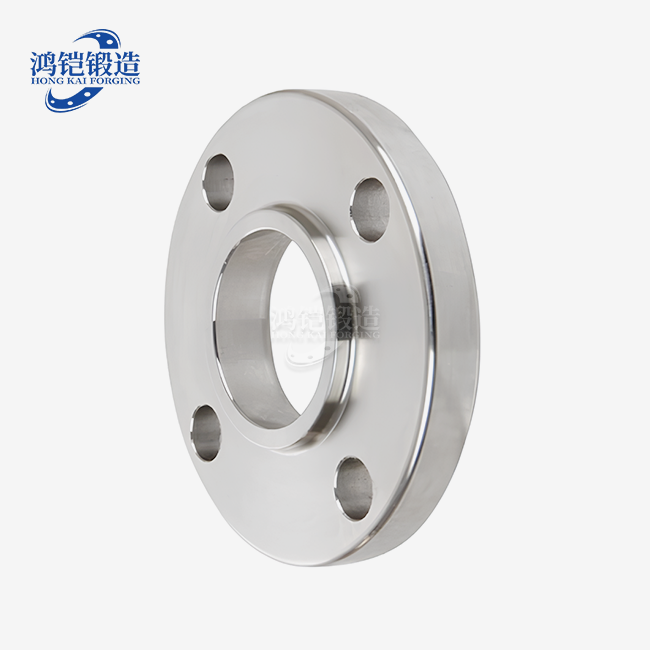

This is a interesting two-part get together comprising of a stub conclusion that gets butt-welded to your pipe and a free backing spine that slides unreservedly over the pipe. This inventive plan permits you to pivot the spine freely without applying push to your channeling system.

The virtuoso of this arrangement lies in its adaptability. You can adjust jolt gaps impeccably with mating flanges without the cerebral pain of torquing channels or managing with misalignment issues. The stub conclusion gives the fixing surface, whereas the backing spine handles the auxiliary loads.

This partition offers colossal focal points in fabric choice. You can utilize costly corrosion-resistant amalgams like stainless steel or Inconel for the stub conclusion that contacts your media, whereas choosing cost-effective carbon steel for the backing flange.

Specification

| Parameter | Specification |

|---|---|

| Standards | ASME B16.5, ASME B16.47, EN 1092-1, DIN, JIS B2220, GOST |

| Size Range | DN15 - DN4000 (1/2" - 157") |

| Pressure Rating | PN6 - PN160 (150# - 2500#) |

| Materials | Carbon Steel, Stainless Steel 304/316/316L, Alloy Steel |

| Face Type | Flat Face (FF) |

| Temperature Range | -45°C to +400°C |

| Testing | Hydrostatic, PMI, Dimensional inspection |

| Finish | Shot blasted, Painted, Galvanized |

Advantages of Lap Joint Flange

Cost Optimization in Corrosive Environments

You spare 40-60% on fabric costs by utilizing costly combinations as it were where required. The stub conclusion handles media contact whereas the backing spine employments conservative materials.

Easy Installation and Maintenance

The rotatable plan dispenses with arrangement battles amid establishment. You can position jolt gaps flawlessly without focusing your channeling system.

Frequent Disassembly Capability

When you require normal upkeep get to, these spines permit speedy disengagement without cutting welds or realigning overwhelming pipes.

Material Flexibility

You can blend and coordinate materials based on your particular prerequisites. Utilize corrosion-resistant stub closes with standard backing spines for ideal execution and economy.

Stress-Free Assembly

The free flange plan avoids pipe twisting amid bolt-up, keeping up your system's judgment and decreasing establishment time.

Applications

Chemical Processing Plants

In forceful chemical situations, our flanges exceed expectations with corrosion-resistant stub closes matched with prudent backing rings. Idealize for corrosive dealing with frameworks where fabric costs matter.

Water Treatment Facilities

Slurry and wastewater frameworks advantage from simple dismantling for cleaning and support. Your upkeep groups will appreciate the fast get to these flanges provide.

Marine and Offshore Platforms

Salt water situations request erosion resistance. These spines provide strength whereas keeping substitution costs sensible through savvy fabric selection.

Food and Pharmaceutical Industries

Sanitary applications require visit cleaning and assessment. The simple dismantling include bolsters strict cleanliness conventions without compromising framework integrity.

Retrofit Projects

When space limitations anticipate pipe turn, the free spine revolution tackles complex arrangement challenges in existing facilities.

Why Choose Us

Shanxi Hongkai Forging brings over decades of manufacturing excellence to every Lap Joint Flange we produce. Our integrated production facility handles everything from forging to final packaging under one roof.

Quality Assurance

We keep up thorough quality control with comprehensive testing counting hydrostatic weight tests, fabric confirmation, and dimensional assessments. Each spine meets or surpasses universal standards.

Global Standards Compliance

Our products conform to ASME, EN, DIN, JIS, and GOST standards, ensuring compatibility with your existing systems regardless of geographic location.

Competitive Pricing

Direct producer estimating disposes of agent costs. You get premium quality spines at factory-direct costs with solid conveyance schedules.

Technical Support

Our designing group gives application direction to offer assistance you select the ideal flange arrangement for your particular requirements.

Proven Track Record

We send out to Europe and Americas with set up client connections built on quality and unwavering quality. Your extend victory is our priority.

FAQ

Q: What's the difference between a lap joint flange and a slip-on flange?

A: The products slide freely over the pipe and work with stub ends, while slip-on flanges are welded directly to the pipe. Lap joints offer rotation flexibility that slip-ons cannot provide.

Q: Can I reuse lap joint flanges?

A: Yes, the backing flange can be reused since it doesn't require welding. Only the stub end needs replacement if damaged.

Q: What gasket types work with these flanges?

A: Standard flat gaskets work well. The stub end's raised face provides proper gasket compression when assembled.

Q: How do I determine the correct size?

A: Match the flange size to your pipe diameter and pressure requirements. Our technical team can assist with selection based on your application.

Q: What delivery times can you provide?

A: Standard sizes typically ship within 2-3 weeks. Custom specifications may require 4-6 weeks depending on complexity.

Contact Us

Ready to discuss your Lap Joint Flange requirements? Contact our technical sales team at kevin.zhao@hkflange.com for expert guidance and competitive quotations.

Clear Communication, and Reliable Technical Support