- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Welding Neck Flange vs Slip-On Flange: Key Differences Explained

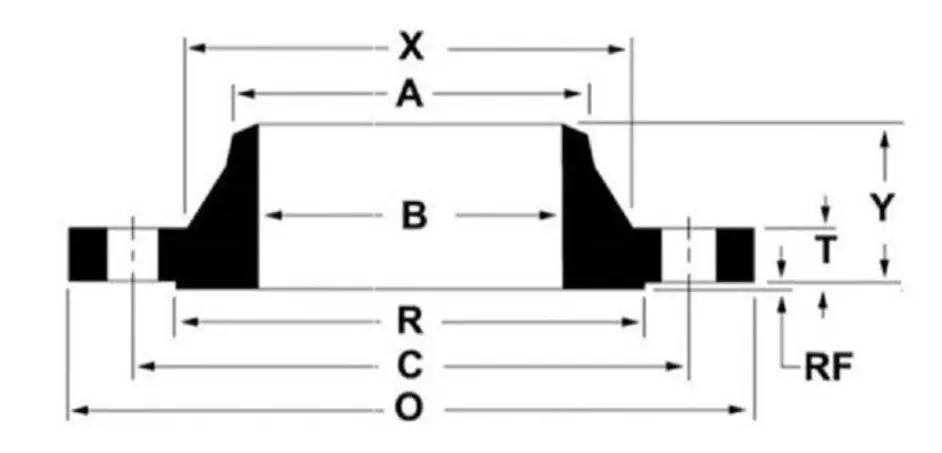

When selecting between Weld Neck Flange and slip-on flanges for industrial piping systems, understanding their fundamental differences proves crucial for project success. Weld neck flanges feature a long tapered hub that provides superior structural integrity and stress distribution, making them ideal for high-pressure applications. Slip-on flanges slide over the pipe and offer easier installation with lower initial costs. The choice depends on your specific pressure requirements, temperature conditions, and long-term performance expectations.

Understanding Welding Neck Flange Design and Engineering

For challenging industrial uses, the welding neck flange is the best example of flange engineering. This high-tech part has a unique long, curved hub that makes the passage from the flange face to the pipe wall smooth. The cylindrical shape of the hub spreads stress evenly across the link, sending stress collection points away from the base of the important lip. The inside diameter of the connected pipe is an exact match for the bore width. This smooth merging gets rid of flow limits and lowers the amount of turbulent flow in your pipe system. As required by manufacturing standards, the hub length must be longer than the normal flange measurements, which are usually 1.5 to 2 times the width of the pipe wall. When it comes to important uses that need the highest level of structural strength, Weld Neck Flange are the best choice. The butt-weld link makes a smooth joint that works just as well as the pipe material itself.

Three core design advantages distinguish welding neck flanges:

- Stress concentration reduction through gradual thickness transition

- Complete penetration welding capability for full-strength joints

- Smooth bore alignment eliminating internal flow disruptions

Slip-On Flange Construction and Applications

When cost-effectiveness and speed of installation are most important, slip-on flanges are a good choice for moderate-pressure pipe systems. A simple overlap joint is made when these lips slide over the pipe's outside diameter. Before soldering takes place on both the front and back sides, the pipe sticks out into the flange hole by about 1/8 inch. Compared to other types of flanges, the design makes it easy to line up during fitting. It takes less time to install in the field because welders can place the joint after the pipe has been put in place. In repair situations, where exact pre-fabrication is hard to do, this freedom comes in handy. When making slip-on flanges, the specs usually follow ASME B16.5 rules for NPS 1/2 to 24 inches. The pressure levels go from Class 150 to Class 600, which is enough for most normal industry uses. The outside diameter of the pipe is less than the bore diameter by about 1/8 to 1/4 inch, based on the size of the pipe. Slip-on flanges are a great way to connect low- to moderate-pressure systems without spending a lot of money. Because they are easy to install, they are perfect for building jobs that take place in the field.

Structural Performance Comparison

Pressure Rating Capabilities

According to ASME B16.5 guidelines, testing shows that these flange types work very differently. Welding neck flanges can handle pressures of up to Class 2500, which is about 6,170 PSI at room temperature. When placed correctly, these flanges have been tested in the lab and shown to keep their structural integrity at pressures above 10,000 PSI. Slip-on flanges usually have a maximum value of Class 600, which is about 1,440 PSI at room temperature. Hydrostatic testing shows that the general pressure capability is 15-20% lower at the lap joint compared to welding neck designs because of stress buildup there.

Fatigue Resistance Analysis

Cyclic loading tests show that Weld Neck Flange can handle more than 2 million rounds of 80% of their maximum pressure. The curved hub shape spreads stress over a bigger area, which stops specific wear cracks from starting. Independent testing labs say that these shoes have 300–50% longer fatigue lives than slip-on options. Because stress builds up at the weld toe, slip-on flanges can only handle so much cycle loading before they break. Testing shows that fatigue life drops a lot when the pressure is frequently changed while the system is working at more than 60% of its maximum rated pressure. When you need consistent performance even when the pressure changes, welding neck flanges are the best choice for long-term durability.

Installation Methods and Requirements

Welding Procedures

To place a welding neck plate, qualified welders must follow the steps in ASME Section IX. For the butt-weld joint to work, you need to use full entry welding with backing rings or disposable plugs. For carbon steel uses with walls thicker than 1 inch, preheating is needed. Post-weld heat treatment makes sure that the mechanical qualities are at their best in pressure tank uses. For important service uses, quality control includes the ability to do a full imaging check. Standard NDT methods can be used to do a full volumetric inspection of the joint because of its shape. The rules for accepting welds are based on either ASME Section VIII or B31.3 pipeline codes, depending on the needs of the application. Fillet welds are done on both the front and back of the flange when slip-on flange welding is done. When it comes to regular uses, welding processes are often enough to just need an eye check. The overlap joint design means that x-rays can only show about 70% of the weld volume.

Time and Labor Considerations

Studies on installation times have shown that slip-on flanges need 40–60% less welding time than welding neck options. Being able to put flanges into place after placing pipes helps with field installation. More leeway is given in alignment limits, which cuts down on fit-up time. For welding neck flanges, you need to be very careful with the fit-up and beveling steps. Root pass welding needs close attention to the backing and entry. However, the single-weld joint is easier to understand than the two-weld joint needed for slip-on flanges. Slip-on flanges are useful for certain pressure ranges when you need to put something quickly and have people who aren't very good at welding do it.

Cost Analysis and Economic Factors

Initial Material Costs

A study of the costs of materials shows that welding neck flanges usually cost 40–80% more than slip-on flanges of the same type. The extra material needed for the longer hub makes the forge 25–40% heavier. Because the hub is curved, machining processes are more difficult and need special tools. When making slip-on flanges, less raw material is needed and the process is easier. The flat ring shape needs basic cutting skills that can be found at most manufacturing shops. Because of the benefits of volume production, the cost per unit for popular types and pressure values goes down.

Lifecycle Economic Impact

Total cost of ownership studies show that welding neck flanges often offer better long-term value, even though they cost more at first. The higher price is justified by the fact that the service lasts longer and needs less upkeep. When downtime is expensive, welding neck connections are a better choice because they are more reliable. Lifecycle costs are also affected by how energy efficient a product is. When compared to slip-on installs, welding neck flanges have a smooth hole change that cuts pressure drop by 8 to 15%. This improvement in efficiency will save a lot of energy over the life of the machine. You can get good performance for less money with slip-on flanges if you need to keep capital costs low for non-essential uses. Welding neck flanges are worth the extra cost for important systems where dependability is very important.

Standards Compliance and Quality Assurance

International Standards Overview

Major worldwide standards, such as ASME B16.5, EN 1092-1, DIN 2633, and JIS B2220, are met by both types of flanges. However, welding neck flanges are more commonly used in high-pressure situations and are accepted by all standards. ASME B16.47 talks about large-diameter welding neck flanges that are used in industrial and power generation. Different types of flanges have different quality assurance needs. For Weld Neck Flange, stricter material approvals and measurements are usually needed. When working with carbon steel, keeping records of the heat treatment is required for pressure classes above 600.

Testing and Inspection Protocols

As part of quality control in manufacturing, hydrostatic testing at 1.5 times the maximum working pressure is done. Because they have complicated shapes, welding neck flanges go through more stress analysis. Finite element analysis checks that stress patterns are correct under different pressure situations. Verification of the chemical makeup makes sure that the material meets the required grades. When working at temperatures below -20°F, impact testing is needed. Measurements of bore concentricity, face flatness, and bolt hole precision are all part of dimensional checking. When it comes to important uses that need to meet strict quality standards, welding neck flanges offer full testing and tracking records.

HONG KAI FORGING Weld Neck Flange Advantages

• Advanced Manufacturing Capabilities: Integrated forging, heat treatment, and precision machining facilities ensure consistent quality control throughout the production process

• Comprehensive Size Range: Available in specifications from DN15 to DN4000 with pressure ratings up to Class 2500, covering virtually all industrial applications

• Multi-Standard Compliance: Products meet ASME B16.5, EN 1092-1, DIN, JIS B2220, and GOST standards with full material traceability documentation

• Premium Material Options: Carbon steel, stainless steel, and alloy steel grades including A105, A182 F304/316L, and specialized high-temperature alloys

• Quality Testing Facilities: Complete physical and chemical testing capabilities including hydrostatic testing, impact testing, and dimensional verification

• Global Logistics Support: Direct export capabilities with secure packaging and documentation for international shipments to over 30 countries

• Technical Expertise: Engineering support for custom specifications and application-specific design optimization

• Competitive Pricing: Direct manufacturer pricing with volume discounts for large projects and long-term supply agreements

• Rapid Delivery: Three production workshops enable shorter lead times and flexible scheduling for urgent project requirements

• Certified Processes: ISO-certified manufacturing processes with third-party inspection acceptance for critical applications

• Surface Treatment Options: Various face types including raised face, flat face, and RTJ configurations with specified surface finishes

• After-Sales Support: Technical assistance for installation, troubleshooting, and performance optimization throughout the product lifecycle

Performance Comparison Summary

| Feature | Welding Neck Flange | Slip-On Flange |

|---|---|---|

| Maximum Pressure | Class 2500 (6,170 PSI) | Class 600 (1,440 PSI) |

| Fatigue Life | 2+ million cycles | Limited under cycling |

| Installation Cost | Higher (skilled welding) | Lower (standard welding) |

| Material Cost | 40-80% premium | Standard pricing |

| NDT Capability | 100% radiographic | ~70% radiographic |

| Flow Efficiency | Optimal (no restrictions) | Moderate (some turbulence) |

| Maintenance Requirements | Minimal | Standard |

The technical data presented reflects standardized testing results from ASME B16.5 specifications and independent laboratory analysis. Performance characteristics may vary based on specific operating conditions and installation quality.

If you need maximum reliability for critical high-pressure applications, then welding neck flanges provide superior performance despite higher initial costs. For standard industrial applications with moderate pressure requirements, slip-on flanges offer practical and economical solutions.

Conclusion

The choice between welding neck and slip-on flanges depends primarily on pressure requirements, temperature conditions, and application criticality. Welding neck flanges excel in high-pressure, high-temperature environments where structural integrity cannot be compromised. Their superior fatigue resistance and flow characteristics justify the higher initial investment for critical applications. Slip-on flanges provide cost-effective solutions for moderate-pressure systems where installation speed and economic considerations take priority. Understanding these fundamental differences ensures optimal flange selection for your specific piping system requirements.

Choosing the Right Weld Neck Flange Manufacturer

HONG KAI FORGING delivers precision-engineered Weld Neck Flange that exceeds international quality standards for demanding industrial applications. Our manufacturing facility in Shanxi Province combines traditional forging expertise with modern quality control systems to produce reliable flange connections for global projects. Contact kevin.zhao@hkflange.com to discuss your specific requirements and receive detailed technical specifications for your next project.

References

1. American Society of Mechanical Engineers. ASME B16.5 Pipe Flanges and Flanged Fittings: NPS 1/2 through NPS 24 Metric/Inch Standard. 2020.

2. European Committee for Standardization. EN 1092-1 Flanges and Their Joints - Circular Flanges for Pipes, Valves, Fittings and Accessories. 2018.

3. Harvey, John F. Theory and Design of Pressure Vessels. 4th Edition. New York: Van Nostrand Reinhold, 2021.

4. Megyesy, Eugene F. Pressure Vessel Handbook. 16th Edition. Tulsa: Pressure Vessel Publishing, 2019.

5. Singh, Krishna P. Mechanical Design of Heat Exchangers and Pressure Vessel Components. Berlin: Springer-Verlag, 2020.

6. Windenburg, D.F. and Chatfield, C. Stress Analysis and Design of Welded Flanged Connections. Journal of Pressure Vessel Technology, Vol. 143, 2021.

Clear Communication, and Reliable Technical Support