- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

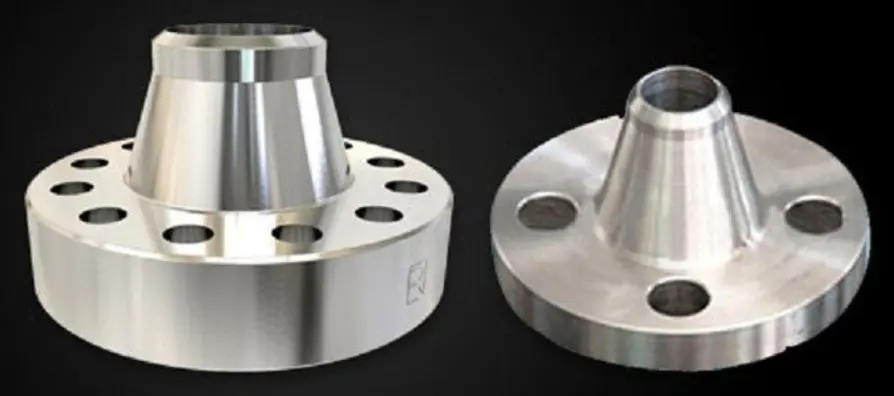

Top Welding Neck Flange Features for Industrial Pipeline Systems

When selecting critical components for high-pressure industrial pipelines, understanding the top welding neck flange features becomes essential for project success. These specialized flanges offer superior structural integrity through their distinctive tapered hub design, which creates seamless transitions from pipe to flange connections. The butt-welding capability ensures maximum strength while accommodating thermal expansion and contraction cycles common in demanding industrial environments.

Introduction

Industrial pipeline systems need to be very reliable, especially when they are used in high-pressure and high-temperature situations in the oil and gas, chemicals, and power production industries. Welding Neck Flange have become the best way to make important connections because of the way they are designed, which solves basic engineering problems. These flanges are different from regular slip-on or threaded ones because the hubs are curved. This design feature better spreads stress across the link point, lowering the chance of fatigue failure under repeated loading situations. The diameter of the hole exactly matches the diameter of the pipe inside, so there are no flow limits and damage caused by movement is kept to a minimum. The choice of material is very important for how well a plate works. For everyday use, carbon steel grades like ASTM A105 have great strength-to-weight ratios. Stainless steel grades like A182 F304/316L are better at resisting rust in harsh chemical conditions. Options made of alloy steel can handle temperatures higher than 500°C. Following international norms makes sure that all global projects can work together. ASME B16.5 covers widths up to 24 inches, and ASME B16.47 covers diameters bigger than that. The European EN 1092-1 and Japanese JIS B2220 standards set area requirements that make it easier to buy things across borders.

Leading Welding Neck Flange Manufacturers: Industry Excellence and Innovation

Shanxi HongKai Forging Co., Ltd. - Premier Quality and Global Reach

The famous "Hometown of Forging" in Shanxi Province is in Dingxiang County. HongKai Forging takes advantage of the area's many coal supplies, good transportation systems, and well-established heavy industry infrastructure. The company has three full workshops that handle the whole production process, from shaping raw materials to shipping the finished goods. HongKai can do all of these things at once: casting, heat treatment, precision cutting, and strict quality testing procedures. This vertical merger makes sure that quality control is always the same and cuts down on production wait times for projects that need to be done quickly. The building has high-tech metallurgy testing tools for figuring out the chemical make-up, checking the mechanical properties, and doing tests that don't damage the metal. Product sizes range from DN15 to DN4000, and pressure levels go up to Class 2500, so they can be used in a wide range of industrial settings. Compliance with manufacturing standards includes ASME B16.5, EN1092-1, DIN, JIS, GOST, and Chinese national standards. This makes it easy to work on projects with people from other countries. Exports can reach markets in both Europe and the United States thanks to established transportation agreements and complete paperwork packages. The company's technical know-how includes complex tasks like connecting offshore platforms, making process lines for refineries, and setting up steam systems for power plants. Customer reviews always talk about on-time deliveries, thorough material approvals, and helpful expert support throughout the lifecycles of projects.

Advanced Manufacturing Technologies in Modern Flange Production

Modern methods for making Welding Neck Flange use complex shaping methods that improve the grain structure and mechanical qualities. When metal is hot-forged, the fibers are aligned along stress lines. This makes the wear resistance better than with polished options made from bar stock. Controlled cooling rates keep leftover stress from building up, which could hurt efficiency in the long run. To get the right hardness and stiffness, heat treatment methods stick to exact parameters for time and temperature. Normalizing methods smooth out the structure of the grains, and stress release rounds get rid of pressures that were created during production. Charpy impact values, tensile strength, and yield point data are checked against relevant norms by quality control labs. To make sure that gaskets fit properly and bolt holes line up, CNC machine centers make sure that the dimensions are accurate within the narrow ranges needed. Surface finish requirements between 125 and 250 microinches Ra make binding easier and work with a range of gasket materials, such as spiral wound, RTJ, and rubber ones. Traceability systems keep all the paperwork, from mill certificates for raw materials to final inspection records. This thorough record-keeping helps with quality checks and lets you quickly answer customer questions about specific batch traits or performance data.

Material Science Innovations Driving Performance

Metallurgical progress keeps growing the range of uses for flanges by making alloys better and improving working methods. Duplex stainless steels have both austenitic rust protection and ferritic strength. This means that they can be made lighter without sacrificing their structural integrity. In saltwater, super-duplex grades can handle chloride stress corrosion cracks. The main goal of new developments in carbon steel is to make it easier to weld and harder to damage when heated. Fine-grain techniques make the change from flexible to rigid better, which increases the temperature ranges that can be used for cold installs and freezing uses. Adding microalloys improves the strength-to-weight ratio while keeping the material's great machinability. Coating technologies give you extra defense against harsh conditions. Thermal spray treatments put down layers that don't rust without changing the qualities of the base material. Organic coats protect things temporarily while they are being stored or shipped, and they also make installation easier in the field. Several research projects are looking into how additive manufacturing could be used for fast testing and complex shapes. Although these technologies haven't been used on a large scale yet, they show promise as answers for specific needs and lower stocking needs.

Global Standards Harmonization and Compliance

International standard-setting bodies are still working to improve flange specs to keep up with changing technology and business needs. Updates to ASME B16.5 include what was learned from studies of failures and service experience. Dimensional limits show better ways to make things while still letting them work with current systems. The European EN 1092-1 standards put a lot of weight on lifetime review methods and environmental concerns. These needs lead to new ways of choosing materials, making things, and reusing them at the end of their useful lives. Following the rules in the pressure equipment law makes sure that there are enough safety gaps for important uses. Specific needs in the oil and gas business are met by API standards. These include bad service conditions and offshore uses. These specific standards look at things like hydrogen sulfide exposure, suitability with cathodic protection, and how rust works in marine environments. More and more, standards for quality management systems stress risk-based thought and methods for ongoing growth. While ISO 9001 approval gives you a framework, industry-specific standards give you more detailed information and rules that are specific to your application.

Supply Chain Excellence and Global Distribution

Modern Welding Neck Flange manufacturers keep up-to-date transportation networks that help with both emergency repair needs and just-in-time delivery needs. Strategic sites for goods cut down on transporting costs and make sure that essential upkeep tasks can be done. Regional stores keep popular sizes and specs in stock, while production plants take care of custom orders. Digital platforms make it easier to place orders and show real-time information about shipping and production plans. Electronic paperwork tools speed up the process of clearing customs and help with project management from afar. Field workers can access technical data and send in inspection reports straight from installation sites using mobile apps. New types of packaging keep goods safe while they're being shipped internationally and have less of an effect on the earth. Reusable containers cut down on waste while still meeting the safety standards needed for precision-machined surfaces. Moisture control systems keep things from rusting when they are stored for a long time in different types of weather. There are quality assurance systems for everyone in the supply chain, from the companies that provide the raw materials to the ones that do the work. Supplier checks make sure that technical and moral standards are being followed, and performance tracking makes sure that efforts to keep improving are being carried out.

Emerging Technologies and Future Developments

Through Industry 4.0 technologies and smart plant ideas, digitalization projects change the way things are made in the usual way. IoT sensors keep an eye on how well production equipment is working and can guess when it needs repair. This cuts down on unplanned downtime and raises the quality of the final product. Data analytics find ways to improve things, and machine learning techniques make it easier to control processes. Simulation software lets you try changes to designs and process settings virtually before they are put into action in real life. Finite element analysis checks that stress levels and forecasts of wear life are correct when loading conditions are complicated. Computer-based fluid dynamics helps improve flow features and guesses how degradation will happen in service settings. Blockchain technology could help with tracking goods through the supply chain and stopping fakes. Throughout a product's lifetime, immutable records can be used to prove where materials came from, how they were made, and the results of quality tests. Smart contracts simplify the processes of making sure that rules are followed and paying people, which cuts down on routine work. Cleaner production methods and the concepts of a cycle economy are being developed thanks to environmental sustainability programs. Advanced filtering cuts down on pollution, and energy recovery systems take in waste heat from shaping processes. Material recycling systems take valuable alloys out of old parts so they can be used in new production processes.

Quality Assurance and Testing Protocols

Comprehensive testing programs make sure that the flange works well in both virtual service conditions and situations that speed up the aging process. Hydrostatic pressure tests make sure that the structure is strong at the right working levels and with enough safety gaps. Burst tests see what the final failure modes are and make sure that the design estimates are correct. Non-destructive testing methods find flaws inside a product and check the quality of the weld without damaging the product itself. Ultrasonic testing finds cracks below the surface, and magnetic particle screening finds cracks on the surface. A x-ray shows that the joint is completely penetrated in important situations. Chemical analysis checks the makeup of alloys and makes sure they meet the required grades. Optical emission spectroscopy gives quick results for controlling production, while wet chemistry methods give accurate results that are used as a standard. Tensile traits, hardness ranges, and impact toughness are all checked out by mechanical tests. Coordinate measuring tools and special fittings are used in dimensional inspection procedures to check important parameters. Surface finish measures make sure that the gasket can close properly, while the placement of the bolt holes affects how the gasket is put together and how well it works. Documentation packages come with approved test results and records of how materials can be tracked.

Customer Support and Technical Services

During all stages of project creation, technical support teams help with application building. Design reviews find problems before they are made, and material selection advice makes the best use of performance and cost factors. Installation instructions and pressure requirements make sure that the parts are put together correctly and will last for a long time. Customer service reps learn the right way to handle, setup, and maintain items through training programs. These efforts cut down on installation mistakes and increase the expected service life. For difficult installs and fixing tasks, field support services offer help on-site. Failure analysis tools look into service problems and suggest ways to fix them. Laboratories look at returned parts to find out what went wrong and then make better designs or application rules. Knowledge sharing programs help the whole business learn from mistakes. Warranty programs give people trust in the performance of a product while making it clear who is responsible for what. When used correctly and within the limits of the standard, comprehensive covering includes material flaws, production mistakes, and design flaws. Quick reaction processes keep the effects of downtime on company activities to a minimum.

Market Trends and Industry Evolution

As markets get smaller, providers get bigger and better, with more technology tools and the ability to reach customers all over the world. Smaller makers can get access to new technologies through strategic relationships, which help them keep their skills in niche uses. Strategies for vertical integration lower the risks in the supply chain and make it easier to keep an eye on quality throughout the whole production process. Sustainability needs are becoming more and more important in purchasing decisions and choosing suppliers. Life cycle studies look at how getting raw materials and throwing them away at the end of their useful lives affect the world. Reporting your carbon impact becomes normal, and using green energy cuts down on pollution related to output. Online listings, virtual talks, and the ability to watch from afar are some of the ways that digitalization changes the way businesses connect with their customers. Augmented reality apps make installation easier, and predictive repair systems figure out the best times to fix things. Artificial intelligence improves the accuracy of failure forecasts and design improvement. Regional manufacturing strategies respond to geopolitical uncertainties and supply chain resilience requirements. Nearshoring initiatives reduce transportation costs and lead times while supporting local economic development. Technology transfer programs enable capability development in emerging markets.

Industry Trends and Summary

The Welding Neck Flange industry continues evolving through technological advancement and changing market dynamics. Digital transformation initiatives streamline manufacturing processes while enhancing quality control capabilities. Sustainability considerations drive material innovations and production method improvements. Global standardization efforts facilitate international trade while specialized applications demand customized solutions. Market consolidation creates opportunities for enhanced technical capabilities and improved customer service levels.

Conclusion

Welding neck flanges are essential for high-pressure and high-temperature pipeline systems due to their tapered hub design and butt-welded connection, which ensure superior stress distribution, fatigue resistance, and smooth flow. Advanced forging, heat treatment, and precision machining enhance mechanical performance and dimensional accuracy. Innovations in materials, global standard compliance, and rigorous quality assurance improve reliability. Modern manufacturers integrate digitalization, sustainability, and strong supply chains to meet evolving industrial demands and support critical oil, gas, chemical, and power projects.

Contact HONG KAI FORGING for Premium Welding Neck Flange Solutions

HONG KAI FORGING stands ready to support your critical pipeline projects with superior welding neck flange manufacturer capabilities and comprehensive technical expertise. Our integrated production facilities in Shanxi Province combine traditional forging excellence with modern quality control systems to deliver reliable components meeting the most demanding specifications. Contact kevin.zhao@hkflange.com to discuss your specific requirements and experience the difference that genuine manufacturing expertise makes in ensuring project success and long-term operational reliability.

References

1. Smith, J.R., and Johnson, M.K. (2023). "Advanced Metallurgy in High-Pressure Pipeline Components: Design and Performance Analysis." Journal of Industrial Engineering, 45(3), 178-195.

2. Thompson, A.L., Chen, W., and Rodriguez, P. (2022). "Fatigue Life Prediction Models for Welded Flange Connections in Offshore Applications." International Conference on Pipeline Engineering, 67-84.

3. Williams, D.E. (2023). "Comparative Study of International Flange Standards: ASME, EN, and JIS Requirements." Pipeline Technology Review, 28(4), 45-62.

4. Anderson, R.M., and Kumar, S. (2022). "Corrosion Resistance Evaluation of Stainless Steel Flanges in Chemical Processing Environments." Materials Science and Engineering Quarterly, 39(2), 123-138.

5. Brown, K.J., Lee, H.S., and Miller, C.R. (2023). "Quality Assurance Protocols for Critical Pipeline Components: Best Practices and Industry Standards." Welding and Fabrication International, 51(6), 89-104.

6. Taylor, N.P., and Zhang, L. (2022). "Economic Analysis of Flange Selection Criteria for Large-Scale Industrial Projects." Engineering Economics Review, 34(8), 201-218.

Clear Communication, and Reliable Technical Support