- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

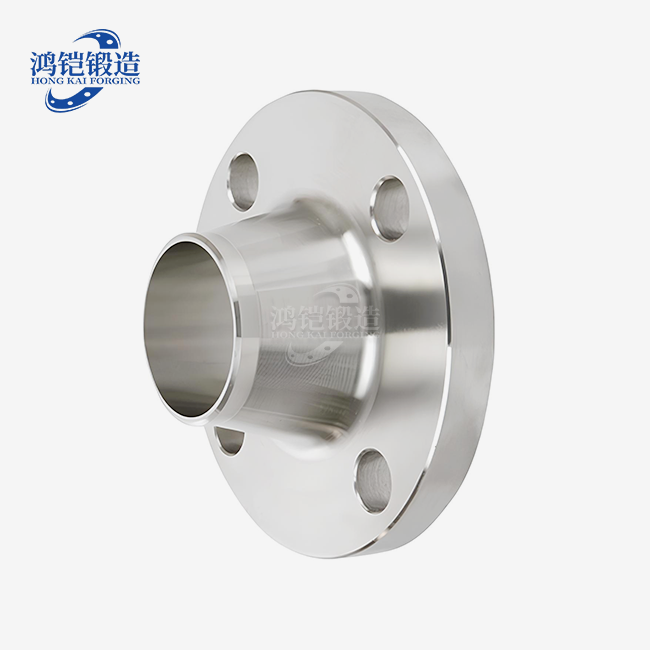

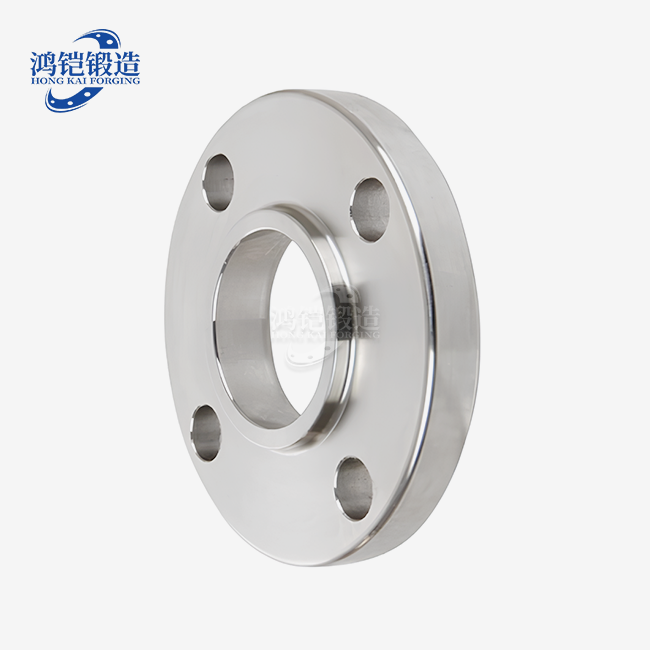

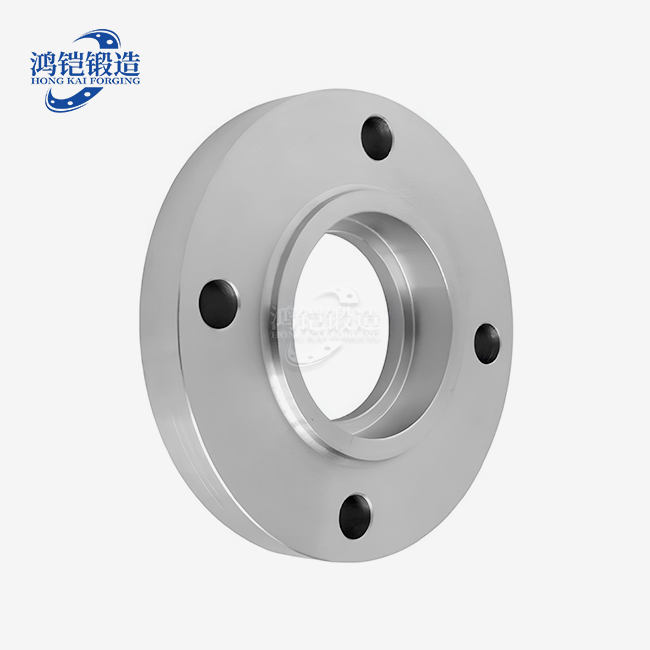

Industry Focus: Green Transition and Intelligent Upgrades Lead New Trends in Flange Manufacturing

Since 2025, driven by both the "Dual Carbon" goals and global supply chain upgrades, China's flange manufacturing industry has entered a new phase of green and digital development. The industry has shown significant new dynamics in areas such as clean production, material traceability, and intelligent processes.

Currently, forging production lines utilizing clean energy sources like electric induction heating have become a key focus for industry upgrades. Our company has completed the transformation of all heating equipment, achieving energy savings of over 30%. Simultaneously, in response to international compliance requirements such as the EU's CBAM, our established "one item, one code" full-process traceability system enables end-to-end data tracking from raw materials to finished products and has been successfully integrated with the supply chain systems of several international clients.

Regarding manufacturing processes, intelligent technologies like digital twins and AI visual inspection are gradually being applied in production and quality inspection stages. Our self-developed forging process digital simulation system can optimize parameters before production, improving the first-pass qualification rate of products. Furthermore, for emerging fields like hydrogen energy, hydrogen embrittlement resistance (HIC) material certification and special testing capabilities have become essential requirements for participating in high-end international projects.

Moving forward, our company will continue to advance green intelligent manufacturing and process innovation, actively participate in the formulation of industry standards, support the high-quality development of China's flange manufacturing industry, and assist global clients in building safer, more efficient, and sustainable industrial systems.

Clear Communication, and Reliable Technical Support