- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

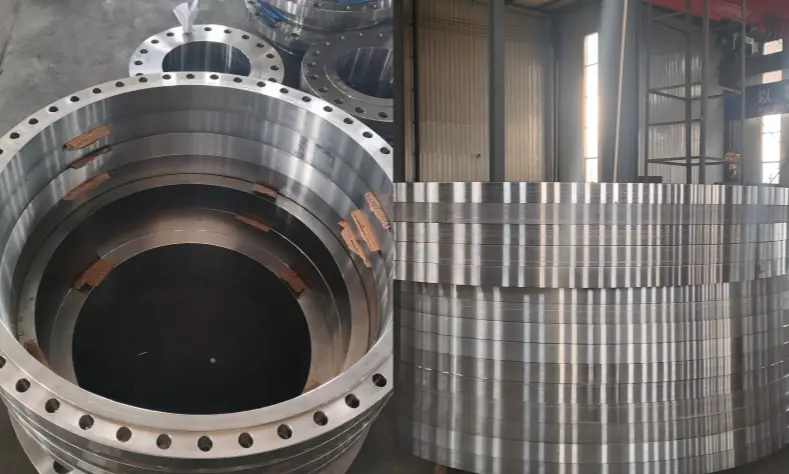

Manufacturing Breakthrough! Successful Delivery of 2.3-Meter Extra-Large Flanges for Italian Energy Project

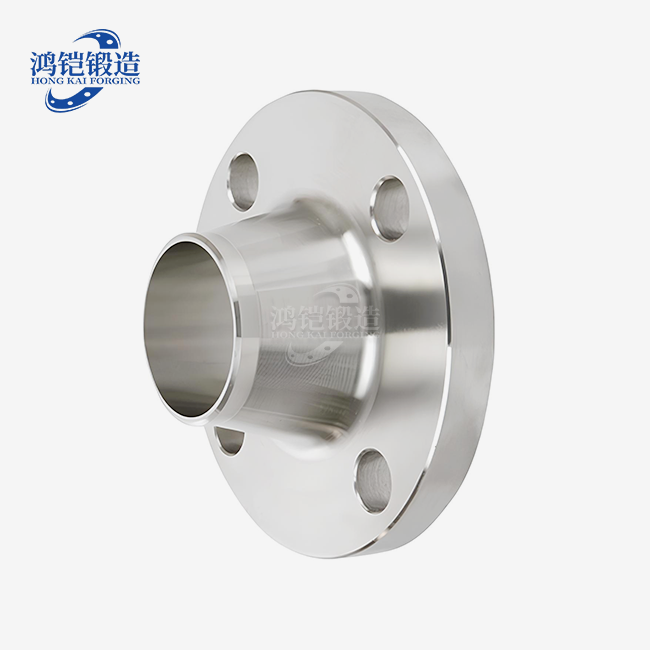

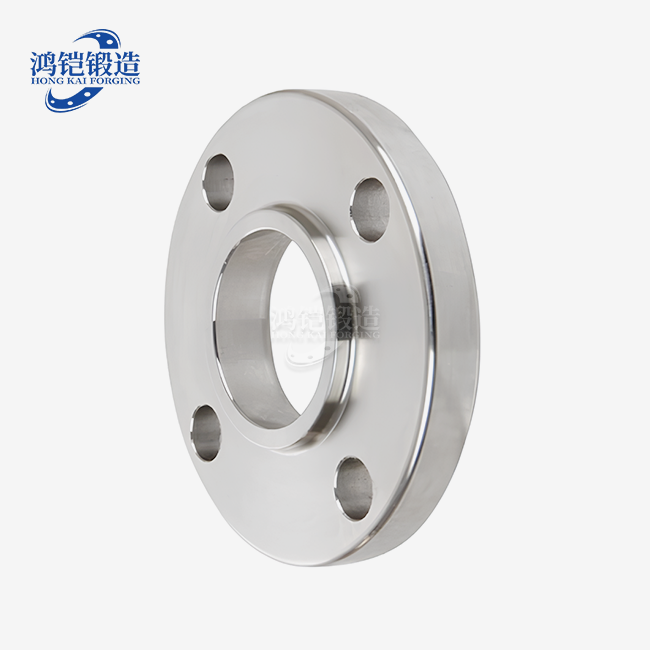

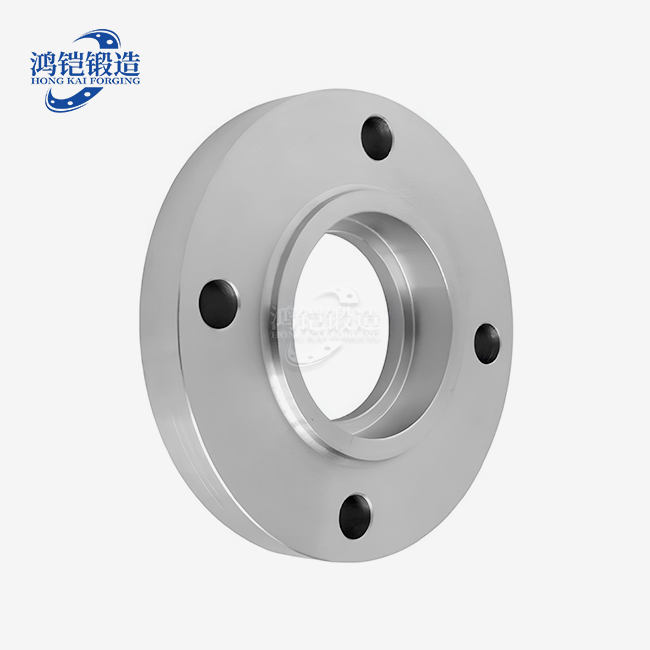

In early 2025, our company successfully completed the manufacturing and delivery of a batch of large welding neck flanges with an outer diameter of 2.3 meters and Class 300 RTJ sealing faces. This batch of products will be used in pipeline connection points at a crucial oil transportation hub in Italy, playing a key role in ensuring regional energy supply security.

Facing multiple technical challenges such as extra-large forging forming, heat treatment uniformity, and high-precision sealing face machining, our company employed a 10,000-ton die forging press for integrated forming processes. Combined with a computer-controlled temperature heat treatment system, we ensured that the material properties fully met the high-standard requirements of ASTM A694 F65. During the machining stage, an extra-large CNC vertical lathe was used to achieve micron-level precision machining of the sealing ring grooves, and comprehensive quality verification was implemented through Phased Array Ultrasonic Testing (PAUT) and Digital Radiography (DR).

The successful delivery of this project marks that our company possesses full-chain control capabilities—from materials and processes to testing—in the field of extra-large diameter, high-pressure class flanges, further consolidating our competitive advantage in the high-end European energy equipment market.

Clear Communication, and Reliable Technical Support