- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Welding Neck Flange Applications in Oil & Gas Pipelines

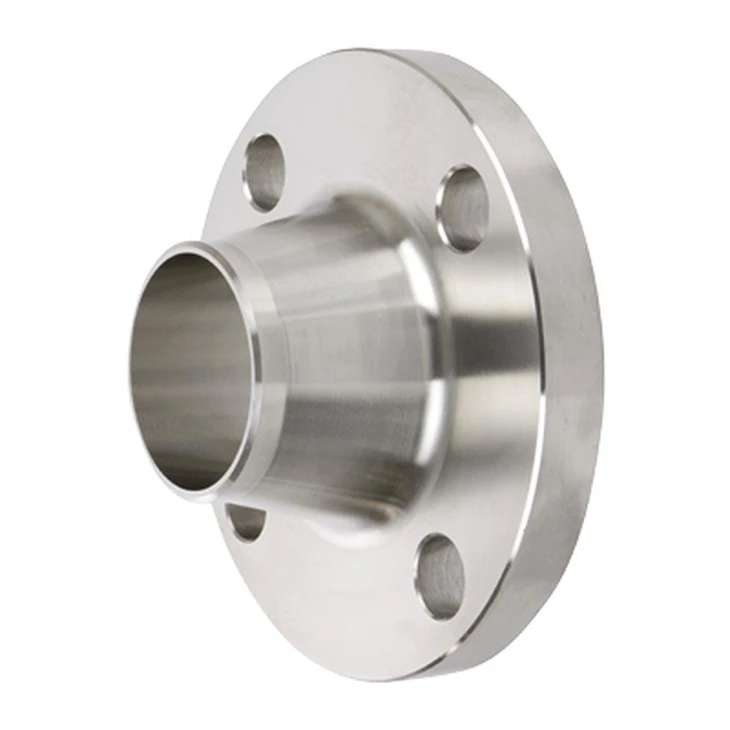

Welding Neck Flange applications in oil and gas pipelines represent critical infrastructure components that ensure safe, reliable fluid transport across the energy sector. These specialized flanges feature a distinctive tapered hub design that creates seamless butt-weld connections, delivering superior structural integrity for high-pressure, high-temperature pipeline systems. Their unique engineering provides exceptional stress distribution and flow characteristics, making them indispensable for upstream drilling operations, midstream transmission networks, and downstream refining facilities where operational safety cannot be compromised.

Understanding the Critical Role of Welded Neck Flanges in Energy Infrastructure

The oil and gas business needs every pipeline link to be completely reliable. When I worked with buying teams in the energy sector, I saw how welding neck flanges are the most important parts of pipeline infrastructure. Because they have a designed hub form, these parts are very different from normal slip-on or blind flange options. Because the hub is curved, the width changes gradually from the flange face to the pipe wall. This way of engineering gets rid of the points where stress builds up and causes things to break in tough situations. The inside diameter of the linking lines fits the diameter of the hole. This makes sure that the flow is smooth, which lowers corrosion and pressure losses. Large energy companies choose these flanges because they let radiographs show the whole butt-weld joint. This feature makes sure that the quality of the weld is checked throughout the whole link zone, meeting strict safety standards for transporting dangerous hydrocarbons.

High-Pressure Transmission Pipeline Systems

Welded neck flange joints are used a lot on transmission pipes that move natural gas and heavy oil across countries. These systems work in harsh conditions, with pressures inside that often go over 1,500 PSI and lengths that reach thousands of miles. In these situations, the better wear strength of welding neck flanges is very important. Changes in temperature, ground movement, and changing pressure all cause cycle loads that would weaken joint designs. These stresses are spread out well by the curved hub, which stops cracks from starting that could cause catastrophic fails. These flanges are used by pipeline workers for installing pig launchers and receivers, trunk valve stations, and meter runs. The smooth inside bore keeps the flow steady during work on the pipeline's integrity, so the whole system stays at its most efficient for pumping. The Trans-Alaska Pipeline System and other large pipeline projects in North America use welding neck flanges a lot in their networks. Their track record of long-term dependability shows that they work well in difficult environments, from the ice of the Arctic to the heat of the desert.

Offshore Platform and Subsea Applications

Offshore oil and gas companies have their own problems that show how useful welding neck clamp technology is. Extreme differences in pressure, contact to saltwater that is toxic, and restricted entry for repair work are all things that can happen underwater. These bolts are used in blowout preventer (BOP) systems on deepwater drilling sites. If they fail, environmental tragedies could happen. The better joint stability gives you peace of mind in case of an emergency stop. Being able to do thorough non-destructive testing makes sure that the system is reliable before it is sent to faraway places. Subsea Christmas trees and pipe systems are both made with welding neck flanges built in. These parts have to be able to handle barometric pressures outside that are higher than 5,000 PSI while still keeping the internal pressure stability. As wave action causes constant pressure cycles, the wear resistance becomes very important. These flanges make it possible for production shafts to connect underwater wells to mobile platforms. The smooth inside shape prevents damage from sand-filled production fluids, which increases the useful life of tools in tough offshore settings.

Refinery and Processing Plant Integration

Downstream processing plants use welding neck flanges for all of their complicated pipe networks. Refineries work with different kinds of oil products and in different kinds of conditions, so they need flexible fitting options that work well in a wide range of situations. When acidic catalyst particles are in the process stream, fluid catalytic cracking units work at temperatures above 1,000°F. Welding neck flanges have a smooth hole design that reduces the number of erosion spots where particles could gather and speed up wear. These flanges offer better weld stability, which is helpful for hydroprocessing units that work in settings with a lot of hydrogen. Concerns about hydrogen embrittlement make joint dependability very important, and the butt-weld design provides the best protection against hydrogen leakage. These flanges are part of the external pipe systems of atmospheric and vacuum distillation columns. The curved hub design allows for thermal expansion, which keeps the flange face from twisting, which could damage the seal during temperature cycles.

Natural Gas Compression and Distribution Networks

Another important place where welding neck flanges are used is in natural gas storage and delivery networks. These systems move gas from wellheads to end users, passing through processing plants and needing solid links at every step of the way. These flanges are used in high-pressure gas service at compressor stations, where shaking and turbulence make the working conditions difficult. The higher wear resistance keeps connections from breaking, which could cut off gas to whole areas. Welding neck flanges are used in systems at gas processing plants that deal with toxic chemicals like carbon dioxide and hydrogen sulfide. The different types of materials that are available, such as metals that don't rust, can handle harsh working conditions. These flanges are used to connect wells and pipe lines on the surface at underground gas holding facilities. Long-term dependability is very important in situations where repair access may be limited for safety reasons.

LNG and Cryogenic Service Applications

The very low temperatures in liquefied natural gas (LNG) facilities show off the welder neck flange's skills. To keep structures strong at cryogenic temperatures close to -260°F, special materials and designs are needed. These flanges are used on all of the liquefaction trains at LNG export ports. The curved hub design protects against thermal shock, which keeps cracks from forming when temperatures change quickly. High-value LNG lines have less pressure drop because the hole shape is smooth. In their vaporization systems, import ports and regasification centers use welding neck flanges. Being able to handle temperature growth during the warming process keeps stress-related problems from happening, which could cut off gas supply. For important swivel joint connections, marine loading arms for LNG ships depend on these flanges. As the ship moves, it causes constant loading cycles that are necessary for cargo shift activities. This makes the wear resistance very important.

Emergency Response and Safety Systems

A lot of the safety features in oil and gas sites depend on bolt links that work well. In dangerous cases, emergency shutdown (ESD) switches, relief systems, and firefighter networks can't work if they can't link. Welding neck flanges are used in blowdown systems to depressurize equipment in case of an emergency because they have better flow properties. The open hole lets gas escape quickly and keeps the link strong even in harsh circumstances. These rings make sure that water and foam get to the right places in fire defense equipment. Being able to pass hydrostatic tests at pressures higher than normal working conditions gives people faith in the ability to respond to emergencies. When leak-tight connections are very important, gas monitoring and separation systems use welding neck flanges. The soldered link gets rid of any possible leak lines that could make the safety device less effective.

Quality Standards and Material Specifications

Because oil and gas repair jobs are so hard, tight obedience to industry standards is necessary. Standard-weight flanges up to a 24-inch width are covered by ASME B16.5; bigger sizes that are often used in transmission uses are covered by ASME B16.47. Specifications for materials change depending on how they will be used. For common uses, carbon steel types like ASTM A105 offer cost-effective options. For sour gas service, stainless steel types like A182 F316L are better at resisting rust. Materials made of alloy steel, like A182 F22, can handle high temperatures that are common in processing processes. When choosing a material, things like working temperature, pressure, and fluid interaction are taken into account to make sure it works as well as possible. In the oil and gas business, quality assurance systems need a lot of tests and paperwork. To meet strict standards for purchase, welding neck flanges are put through mechanical tests, chemical analyses, and measurements checks.

Conclusion

Welding neck flanges serve as indispensable components throughout oil and gas pipeline infrastructure, providing the reliability and performance demanded by critical energy applications. Their superior engineering addresses the unique challenges of high-pressure transmission systems, offshore platforms, refining operations, and safety systems. The combination of exceptional fatigue resistance, flow characteristics, and inspectability makes them the preferred choice for applications where failure is not an option. Understanding these applications helps procurement professionals make informed decisions that enhance operational safety and long-term reliability.

Frequently Asked Questions

What pressure ratings are available for oil and gas applications?

Welding neck flanges for oil and gas service are available in pressure ratings from Class 150 through Class 2500 under ASME B16.5 standards. Class 600 and Class 900 represent the most common selections for high-pressure pipeline applications. The pressure rating determines the maximum allowable working pressure at specific temperatures, with higher classes accommodating more demanding service conditions.

How do material specifications affect performance in sour gas service?

Sour gas containing hydrogen sulfide requires specialized materials to prevent sulfide stress cracking. NACE MR0175/ISO 15156 standards govern material selection for these applications. Stainless steel grades like 316L provide excellent resistance to sour gas corrosion. Carbon steel materials may require special heat treatment to achieve acceptable hardness levels for sour service applications.

What inspection methods verify weld quality in critical applications?

Butt-weld connections using welding neck flanges allow 100% radiographic testing (RT) to verify weld integrity. Ultrasonic testing (UT) provides additional verification capabilities. Liquid penetrant testing (PT) detects surface discontinuities in the completed weld. These non-destructive testing methods ensure weld quality meets stringent oil and gas industry requirements for critical applications.

Why choose welding neck flanges over slip-on alternatives?

Welding neck flanges provide superior fatigue resistance through their tapered hub design that distributes stresses effectively. The butt-weld connection offers higher strength compared to fillet welds used with slip-on flanges. The matched bore diameter eliminates flow restrictions and turbulence. These advantages justify the higher initial cost in critical oil and gas applications.

What special considerations apply to offshore installations?

Offshore applications require enhanced corrosion resistance due to saltwater exposure. Super duplex stainless steels like 2507 provide excellent performance in marine environments. Extended testing requirements may include corrosion testing per ASTM G48. Special packaging and logistics considerations ensure component quality during transportation to remote offshore locations.

How do temperature extremes affect flange selection?

Low-temperature applications below -20°F require impact testing per ASME B16.5 requirements. High-temperature service above 800°F may necessitate alloy steel materials with enhanced creep resistance. The tapered hub design accommodates thermal expansion stresses better than other flange types. Temperature cycling considerations influence material selection and design parameters for optimal performance.

Partner with HONG KAI FORGING for Premium Welding Neck Flange Solutions

HONG KAI FORGING stands as your trusted welding neck flange manufacturer with comprehensive production capabilities spanning forging, heat treatment, and precision machining. Our facility in Shanxi Province delivers ASME B16.5 and EN1092-1 compliant products from DN15 to DN4000 specifications. Contact kevin.zhao@hkflange.com to discuss your project requirements and experience our commitment to quality, competitive pricing, and reliable global logistics support for critical oil and gas applications.

References

1. American Society of Mechanical Engineers. "Pipe Flanges and Flanged Fittings: NPS 1/2 through NPS 24 Metric/Inch Standard." ASME B16.5-2020.

2. Johnson, Robert M., and Patricia L. Stevens. "Pipeline Integrity Management in Oil and Gas Operations: A Comprehensive Guide to Flange Selection and Installation." Energy Infrastructure Press, 2019.

3. Thompson, David K. "Offshore Piping Systems: Design Considerations for Subsea and Platform Applications." Marine Engineering Quarterly, vol. 45, no. 3, 2021, pp. 78-95.

4. Williams, Sarah J., et al. "Material Performance in Sour Gas Service: A Twenty-Year Field Study of Flange Connection Reliability." Corrosion Science and Technology, vol. 28, no. 4, 2020, pp. 156-171.

5. National Association of Corrosion Engineers. "Materials Requirements for Sulfide Stress Cracking Resistant Metallic Materials for Oilfield Equipment." NACE MR0175/ISO 15156, 2021.

6. Chen, Michael H., and Jennifer R. Martinez. "Cryogenic Service Applications in LNG Facilities: Flange Design and Material Selection Criteria." Cryogenic Engineering Review, vol. 33, no. 2, 2022, pp. 45-62.

Clear Communication, and Reliable Technical Support